What new skills, roles, teams, or new internal functions will manufacturers need in 2030? By Jim Hefti

The year 2020 has been a period of great disruption has put many manufacturers in survival mode — and pursuing Industry 4.0 as a lifeline. Over the next decade, digital transformation will be in full force with accelerated digitalization and data-driven intelligence initiatives. By 2030, when the dust starts to settle, the now-digital industrial companies will require new organizational structures and leadership roles to align the culture with the new reality.

Early adopters of the industrial internet of things (IIoT) and data analytics are already developing a deeper understanding of their potential to drive better outcomes. Consider the maintenance organization: Manufacturers and industrial service providers are deploying IIoT sensors on critical equipment to capture real-time performance and condition data, and smart analytics to derive intelligence from the data. For instance, when a precursor to bearing failure is detected in vibration signal patterns, predictive maintenance (PdM) is automatically specified to prevent costly unplanned downtime.

Ahead of the curve are companies pursuing AI-powered analytics such as machine learning (ML), deep learning, computer vision, and natural language processing; digital twins for asset modeling and simulations; prescriptive maintenance (RxM), which is predictive but also prescribes recommended actions; and control tower-type command centers, whether within the organization or as a service, that support remote monitoring and management of consolidated analytics from a 24/7, 360-degree view of how the manufacturing enterprise is performing.

In 10 years’ time, when digitalized workplaces become the norm, there will be fewer people on the factory floor doing preventive or emergency maintenance, and many more behind the scenes using data-driven technologies to drive proactive strategies such as remote monitoring, predictive analytics, root cause analysis, and more. Adapting the manufacturing workforce to this inevitability is a pressing priority.

The key to successfully transitioning from digital transformation to ongoing digital optimization is forward-thinking leadership and a constructive culture — one that includes more people in defining the future of the company and its technology. From the highly technical skilled workforce to senior leadership and trusted external partners, inviting diverse, forward-thinking perspectives is essential to organizational effectiveness and to unleashing innovation, growth, and new business models.

“Organizational development and continuous learning are increasingly digital, immersive, and experiential.”

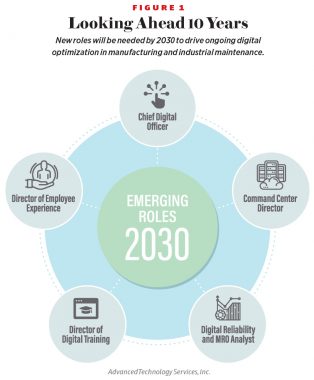

Following are various emerging roles that will be needed by 2030 to drive continuous digital optimization in manufacturing and industrial maintenance:

Chief Digital Officer: The CDO is a tech-savvy, visionary senior executive tasked with leading the digitally transformed enterprise and ensuring it remains technologically current, cohesive, synergistic, and secure. By now, the information technology (IT) and operational technology (OT) cultures have converged, enterprise visibility is in place, and smart analytics are helping operations, maintenance, and supply chain management to continuously improve. The CDO ensures the data and analytics infrastructure will continue to provide solid intelligence for improving efficiency, sustainability, quality, reliability, and profitability — whether internal resources or outsourced service partners are used.

Command Center Director: The analytics-savvy CCD oversees the digital command center that consolidates all operations, maintenance, and MRO supply chain analytics for performance monitoring and troubleshooting by digital analysts — from remote or in the center. For manufacturers, the command center provides cross-organization, cross-site, and enterprise-wide visibility to improve analyst decision making. For comprehensive maintenance and MRO service providers, the benefits extend to cross-customer and cross-industry insights. The CCD ensures reliable uptime of the center and availability of comprehensive data analytics, including continually fine-tuning the quality and substance of the center’s content and facilitating novel sources and applications.

Digital Reliability and MRO Analysts: Much like today’s gamers, those who hold command center digital analyst roles must be able to nimbly and holistically navigate and process streaming flows of critical information from multiple areas, and make consequential decisions. They are also ML specialists who understand and can develop new pattern-recognition algorithms to improve the analytics, diagnostics, actions, and outcomes.

- Digital Reliability Analysts, successors to hands-on Reliability Engineers, remotely ensure equipment reliability by monitoring the command center’s sensor-based analytics, applying modern modeling and simulation techniques, and providing proactive PdM or RxM guidance to the plants to avoid unplanned downtime. They leverage equipment analytics to improve similar equipment used elsewhere in the enterprise, and track failures to eliminate low-performing brands. They can also target maintenance for when production is the lowest and MRO parts are available. DRAs employed by comprehensive maintenance service providers have the added benefit of gleaning and leveraging insights across multiple customers and industries.

- Digital MRO Analysts use the command center to monitor and optimize the MRO supply chain and ensure parts are on hand when needed. The in-plant or service-provided analyst uses the analytics to address inventory requirements, right-size inventory levels, choose which supplies to automatically replenish, streamline the supply network to fewer, trusted suppliers, and more. Analysts for comprehensive MRO service providers can also oversee distributed parts sourcing, refurbishments, and repairable and obsolete parts sourcing, and they benefit from economies of scale.

Director of Digital Training: Organizational development and continuous learning are increasingly digital, immersive, and experiential. Virtual classes, virtual reality, augmented reality, remote live support, and online learning are displacing in-person training. The DTD supports the digitally transformed enterprise by ensuring there is an effective array of digital tools and curriculum for new and refresher training, retraining, and reskilling. With plants changing so rapidly, it is crucial for manufacturers and manufacturing service partners alike to attract fresh tech-savvy talent while keeping experienced employees relevant and retaining their critical knowledge.

Director of Employee Experience: If the company culture is the frame of a house, experience is all the things inside the house. In industry, this includes technology, lighting, ergonomic seating, robot and cobot interaction, service partner interaction, etc. The DEE focuses on improving everything important to the daily employee experience in order to improve their well-being and increase productivity, satisfaction, and retention. The role is especially vital for attracting and engaging younger talent, with their fresh perspectives and digital experience, who may prefer mind-work over muscle-work. Blending different generational perspectives adds value throughout the organization.

Maximizing investments in Industry 4.0 technology and the human resources to support it requires establishing a digital mindset and culture, creating suitable organizational roles and functions, and removing barriers to collaboration. With effective planning and organizational development, manufacturers will be ready to seamlessly transition from digital transformation to digital optimization. M

FOOTNOTES

1 Niall McCarthy,” Rise of the Machines: The Countries with the Highest Density of Robot Workers,” Forbes, Sep 28, 2020, https://www.forbes.com/sites/niallmccarthy/2020/09/28/rise-of-the-machines-the-countries-with-the-highest-density-of-robot-workers-infographic/amp

2 Ibid.

3 Emil Protalinski, “Boston Dynamics CEO talks profitability and the company’s next robots,” Venture Beat, Sep 14, 2020, https://venturebeat.com/2020/09/14/boston-dynamics-ceo-profitability-roadmap-next-robots/

4 Manufacturing Leadership Council, “Vision 2020: The Factory of the Future,” 2017. https://www.mljournal-digital.com/meleadershipjournal/ february_2017? pg=25#pg25

5 Art Markman, “How You Define the Problem Determines Whether You Solve It,” Harvard Business Review, June 6, 2017, https://hbr-org.cdn.ampproject.org/c/s/hbr.org/amp/2017/06/how-you-define-the-problem-determines-whether-you-solve-it

6 Manufacturing Leadership Council, “Vision 2020: The Factory of the Future,” 2017.

7 Niall McCarthy,” Rise of the Machines: The Countries with the Highest Density of Robot Workers,” Forbes, Sep 28, 2020, https://www.forbes.com/sites/niallmccarthy/2020/09/28/rise-of-the-machines-the-countries-with-the-highest-density-of-robot-workers-infographic/amp/[/et_pb_text][/et_pb_column][/et_pb_row][/et_pb_section]