People Powered

Why putting humans front and center in digital transformation is an essential component to success.

TAKEAWAYS:

● Organizational transformations are vital, yet they often fail because they are approached as a rational business journey and not as an emotional journey undertaken by employees.

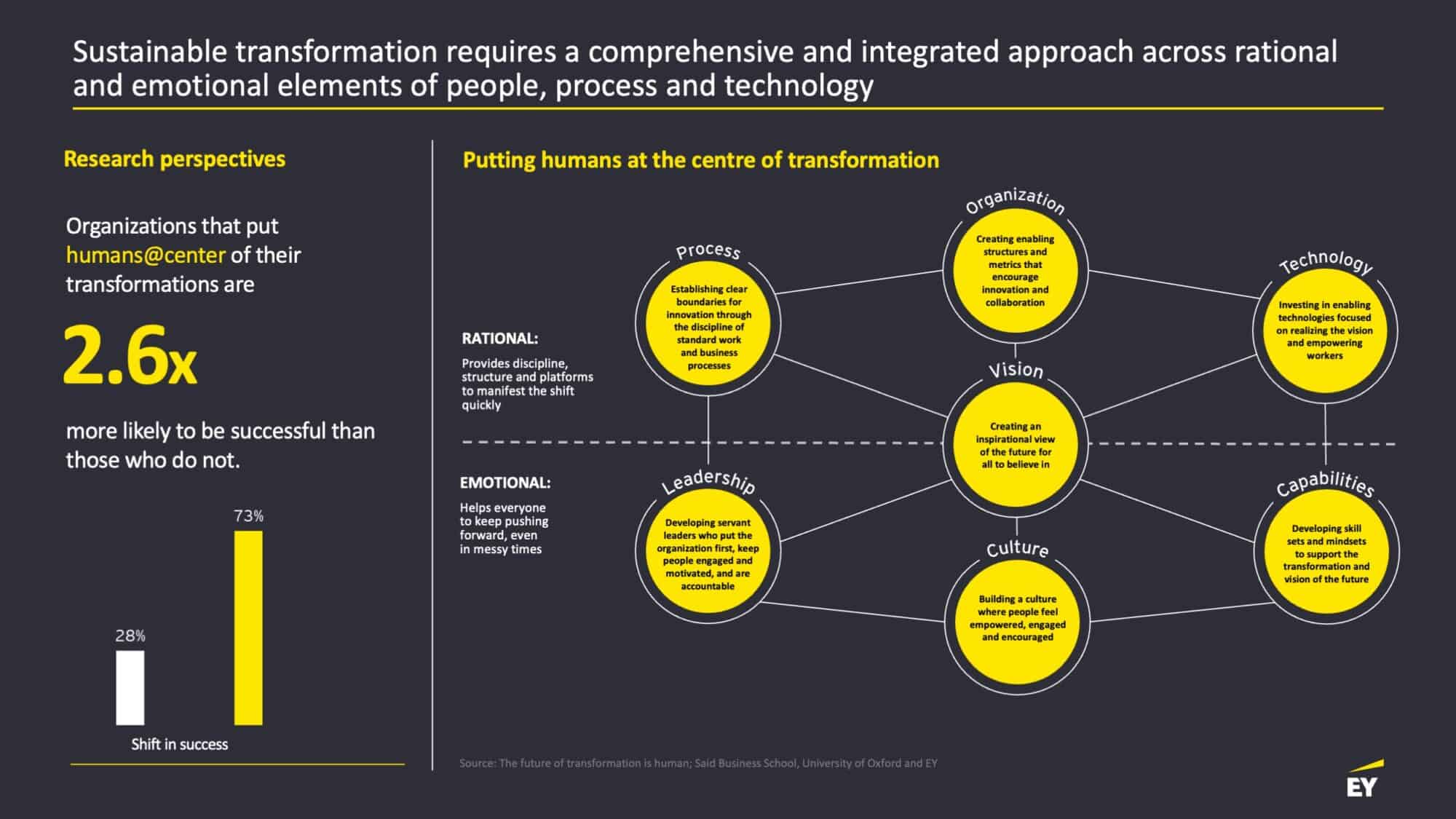

● Research shows that manufacturers that focus on and invest in their people are 2.6 times more likely to succeed in their transformation efforts.

● There now is a framework of seven key interconnected and mutually reinforcing elements manufacturers can use to achieve and sustain a succesful transformation journey.

Manufacturers today face many challenges, from changing customer demands to rapidly evolving technology to persistent internal and external competitive disruptions. These are compounded by the exogenous risks of climate change, global health crises, geopolitical tensions, and political market interference.

Because of these ongoing challenges and risks, manufacturers need to transform successfully — and continuously. Their ability to thrive now depends on the agility with which they can quickly change to meet shifting customer, employee, investor, societal, environmental, technological, and regulatory factors.

Yet many manufacturers continue to struggle with such transformation. Why? Ernst & Young LLP (EY US) and the Saïd Business School University of Oxford teamed up on research1 to find out. We studied the complex factors behind the high failure rate of transformations and explored how leaders can drive transformations that result in lasting change.

“Organizational transformations fail because they approach transformation as a rational business journey and lack sufficient attention to the human conditions that drive success.”

We found that organizational transformations fail because they approach transformation as a rational business journey and lack sufficient attention to the human conditions that drive success. Conversely, those that succeed also focus on, and invest in, their people — and their people’s emotional journey — from the beginning. In fact, the research found that organizations that take this approach are 2.6 times more likely to have successful transformations than those that don’t.

Putting Humans at the Center

EY US calls this putting humans at the center of transformation, which involves addressing both the rational (processes, organizational design, and technology) and the emotional (leadership, culture, and capabilities) aspects of the journey in a balanced and integrated way.

Investment in the rational aspect provides discipline, structure, and platforms to manifest the shift quickly, while the emotional investment helps to keep everyone pushing forward, especially when things get messy. Historically, leaders have focused on the rational, logical parts of transformation. These, of course, are critical — they’re the foundation of how the business operates. Yet our research also shows the importance of the emotional journey — fostering positive instead of negative feelings among those involved — to the success or failure of a transformation. Keys to the emotional side include leaders who engage and rally their people around the change, a culture that encourages people to take ownership of the new ways of working, and capability-building to ensure that people are equipped to thrive in the new environment.

Building on these insights, we have converted what were identified as key drivers of successful transformation into a framework that can be used to stress test the likely efficacy of any given transformation program. (Figure 1) This framework consists of seven interconnected and mutually reinforcing elements — centered on a compelling vision, or an optimistic view of the future in which everyone can believe — that address the critical rational and emotional enablers of a successful and sustainable transformation journey.

Figure 1: A framework for putting humans at the center of transformation

What’s Behind the Failure to Launch?

Based on our research and extensive experience in supporting transformation programs, we believe that companies need to adequately and concurrently address all seven areas of the framework to succeed. Unfortunately, this is where many manufacturers fall short. They may have comprehensive strategies and plans in a few areas, or even most of them. However, they are missing the mark on others, which is compromising their ability to get the most from their efforts.

For example, one automotive manufacturer had highly documented, well-written processes — there was no doubt what people needed to do to execute their jobs. But this wasn’t translating into the results that the company expected. A big reason was that the company lacked a compelling transformation vision that connected with employees. People knew what they were expected to do, but didn’t know why they were supposed to do it.

In another company struggling to make headway in its transformation, leaders, while acting with good intentions, were unknowingly thwarting change efforts. Essentially, they put accountability before capability. They expected workers to inherently understand new processes as well as they did. They weren’t giving workers the time and psychologically safe environment to explore and try out the new ways of working before holding them accountable for performance. They also underestimated the amount of capability-building needed for many of the workers to become proficient and effectively deliver on the shop floor.

“We believe that companies need to adequately and concurrently address all seven areas of the framework to succeed. Unfortunately, this is where many manufacturers fall short.”

A third company wasn’t getting results because it hadn’t identified the new incremental tasks that employees were expected to perform. The company had a massive three-ring binder that spelled out in minute detail its focus on building a future state culture. But leaders hadn’t taken the crucial next step to define what that means for people on the shop floor. Exactly what do workers need to now do differently on a daily basis? Workers weren’t disinterested in participating. They simply didn’t understand how to participate properly.

One of the most common obstacles that companies face is a mismatch between two of the rational elements: process and technology. This was the case at a global multinational manufacturer that was rolling out new software applications. The company felt that it had done all the right work up front to define the use cases and requirements and to pilot them at lighthouse sites, but still struggled with end-user adoption as it deployed the tools at scale. It turned out that the company hadn’t confirmed that the system was consistent with how the organization actually worked, and people weren’t interested in trying something new when they felt their current ways of doing things worked just fine.

A Practical Way to Get Started

As the above examples illustrate, inadequately addressing the human elements of transformation in conjunction with the more rational ones from the beginning most often results in, at best, tepid results and, at worst, outright failure.

How do other manufacturers avoid such outcomes? The obvious answer is that they begin by ensuring that there’s sufficient investment in, and attention to, each of the seven elements of the framework, as outlined in Figure 1. At the same time, it can take significant time and resources to initiate and align these seven elements. We’ve developed a very pragmatic approach that can be adopted at a manufacturing line, site, or network level to help lay a foundation for successful and sustainable transformation. Recognizing a company’s people (particularly those on the production line) will ultimately adopt and drive change, and our approach focuses in on changing day-to-day behaviors in a way that ultimately drives a positive shift in organizational culture.

Practically speaking, this starts with a laser focus on daily tasks. In our experience, the best way to spur behavior change is to first have people learn by doing. This means that leadership identifies a handful of key tasks for people to perform, trains them on the established standard (or current best practice) for each task, and sets them loose to implement the standard (while ensuring that people feel safe enough to make mistakes). The tasks are selected to address key performance improvement opportunities or personal pain points for operating teams, and they may involve leveraging new technology.

People quickly recognize that doing things the right way leads to better performance and a more pleasant job experience — the impact is clearly visible — which inspires confidence in the new way of working and eagerness to embrace it. Importantly, tasks should be explicitly tied to specific targets that teams must hit to help the company achieve its business goals. This helps people understand the direct link between their actions and the success of the business.

“Ultimately, when an organization gets a critical mass of behavior change — say, an entire team on the shop floor — it experiences the dawn of a new culture.”

Soon, with the right support, capability building and context, this new way of working becomes a habit, as people understand that doing things a certain way is just part of their daily job. Now it’s second nature, and the thought of doing things any other way isn’t an option. It’s like when people have progressed in a new exercise regimen and reach a stage where the possibility of not working out or running doesn’t even enter their minds. Here, leadership plays a key role in giving workers intellectual freedom with execution accountability, and in coaching to continue reinforcing the importance of maintaining discipline in how tasks are done so people want to continue doing things the right way even in the face of disruptions that could otherwise distract them.

Eventually, people reach the point at which they intellectually and emotionally know that it’s through the execution of those tasks that they have a better working day. And that’s when they begin to experience an actual behavior change. The timeline for reaching this stage varies by individual. Some people are highly engaged and get there quickly, while others take longer to see things play out. Here again, leadership must remain an active coach — ensuring focus, monitoring ongoing performance with periodic check-ins, demonstrating how people’s actions are addressing the relevant business targets, and encouraging people to actively look for new areas in which they can improve.

Ultimately, when an organization gets a critical mass of behavior change — say, an entire team on the shop floor — it experiences the dawn of a new culture. Everyone is doing their jobs according to the new performance-enhancing standards they’ve defined for their specific tasks (often with the help of new technology), and are updating those standards as necessary as they solve additional problems and learn ways to do things even better. Once established, this new culture and mindset can serve as a crucible of workers’ ideas for solving other problems beyond the shop floor — for instance, a sustainability challenge or any kind of inefficiency — because people now trust the process and the tools, and believe in them because they know that they work. This is when transformation really generates outsized and sustainable returns for the enterprise.

Put Humans at the Center

Today’s manufacturers stand at the precipice of an uncertain world. The nature and impact of disruption are accelerating, intensifying the need for manufacturers to transform. Leaders recognize the critical need for transformation, but many are unsure how to drive it successfully, or, in some cases, they are reluctant to deal with the potential risk involved. Many are still recovering from previous transformation efforts gone awry and are skeptical that a new one will turn out any better.

As our research has found, the key to transformation that delivers significant, sustained performance improvement is putting humans at the center of it all. This means addressing both the rational and emotional aspects of the transformation journey, underpinned by a compelling vision for the future in which people can believe.

A manufacturer’s power is truly in its people. And it’s time for all manufacturers to harness it to build a better business for today and tomorrow. M

About the authors:

Craig Lyjak is a Principal leading EY’s global Manufacturing Transformation solutions. As the leader of the EY/P&G alliance he leads a team focused on innovating methods and tools to create more effective, efficient, and sustainable transformations.

Paul Vail is a Partner in EY Canada’s Business Consulting Practice, Digital Supply Chain and Operations, as well as the Advanced Manufacturing and Mobility Consulting Leader for Canada.

1. As reported in “The Future of Transformation Is Human,” EY and University of Oxford Said Business School, 2022. The research involved a survey of 935 senior leaders and direct reports, as well as 1,127 workforce members from 23 countries and 16 industry sectors. Most respondents had led, or experienced, multiple transformations—both successful and underperforming.