Technology-Driven and Human-Centered

Digital will drive manufacturing’s transformation, but only if it goes with a people-first approach By Sachin Lulla and Himanshu Khandewal

COVID-19 has placed unprecedented challenges on manufacturing companies, which have been forced to adapt to supply chain interruptions, market shifts and labor shortages caused by the pandemic. But with this challenge has come opportunity to reimagine work, transform operations, and emerge with more agility, resiliency, and ingenuity than ever before.

A recent survey conducted by Ernst & Young LLP with 6,000 C-suite executives showed that, while the No. 1 emphasis for reopening is employee safety, 63% of companies are focused on a physical return and a reimagining of work, while 58% are using this time as an opportunity for transformation. However, there has been a fundamental and much-needed shift in approach from process or technology first to people first.

As future resilience and agility become increasingly critical, the human-centered factory of the future helps to plan, prove, and scale value, defining your journey to becoming a data-driven, resilient enterprise with a culture of innovation.

With every highly strategic, large-scale initiative, there are always the following questions: How do we determine what comes first, and what are the essential components to drive success? A large industrial manufacturer based in the Midwest asked us this exact question, with a focus on how it could create a highly collaborative, human-centered factory while maximizing the value derived from technology-enablement. Here’s what we told them.

Understand the Now …

To build the path to where you want to go, you should first be clear about where you are today. Benchmarking can be a strategic first step to understanding your competencies across the organization and determining whether their general terms and conditions provide the highest degree of leverage. We developed an assessment tool in the form of a questionnaire that we send out to individuals based on their areas of scope.

An objective benchmarking process can often uncover problems that an organization doesn’t even realize it has. Take the manufacturer we mentioned above. When we sent the questionnaire to employees throughout the company to get a feel for how they viewed the business, the responses projected a mostly positive image. The company saw its operational structure as developing and, in some cases, established in terms of its maturity. It wasn’t until we moved to the next phase and started interviewing employees that we learned about the considerable pain points that existed.

A deeper understanding of pain points and where value can be unlocked, along with the tools that are available to help, can create a road map for much stronger alignment.

Processes were not integrated, which made demand planning difficult and hurt productivity. Electronic data interchange orders would often have issues, requiring manual remediation, and pricing was managed via spreadsheet, making it difficult to respond to market conditions. We also heard things like people can’t work any harder, they need to be better equipped with technology, and they should have more robust strategies to inform their decision-making process. Concern was also expressed about too much overtime being used and even some safety issues.

In short, there was a lot of extra work being done simply to keep up with current demand. The company was reacting to problems as they arose, rather than coming up with proactive solutions to head off the challenges in the first place.

… Then Look to the Next and Beyond

Based on the data collected from the survey and interviews, we gathered the company’s leadership team and shared best practices of leading manufacturers that are already operating at a high level. We showed them what digital demand planning looks like when you apply AI and what a control tower looks like, along with the capabilities it provides to better sense and respond to supply chain dysfunction.

They were inspired by what’s in the beyond while also working in the now to find some quick wins and foundational capabilities in which they could invest to begin moving forward. You can’t solve every problem all at once. When you have a deeper understanding of your pain points, and you start to see where value can be unlocked, along with the tools that are available to help, you can create a road map that will lead to much stronger alignment.

There is an old axiom that can get you in the right mindset as you approach the transformation of your business: “You can’t get there from here, but you can get here from there.” All too often, when companies embark on a remake of their business, they don’t have a clear enough picture of the north star and what they want to be. And even if they do, they often build their plans based on how they operate and what they see in their company in that moment rather than what they’re building toward.

Inevitably, when they are done, they find they’re not satisfied with the results because they haven’t really transformed what they do. In a sense, they’ve just rearranged the furniture and moved people around a bit. They haven’t really changed the vision. They haven’t allowed themselves to look beyond what their company does and really think about what it could be.

As we talk to clients, the first thing they’ll often say is, “Tell us what great looks like.” The EY-Nottingham Spirk Innovation Hub1 was launched, in part, to help clients answer that question and be inspired by real-world solutions and demonstrations of what companies are doing to achieve Industry 4.0.

This gets back to that idea of focusing on people and building a human-centered operation. Data and technology can help inform your decisions and enable you to develop the road map to guide your journey. But it’s people and their insight, creativity and thoughtful analysis that can drive your company forward.

What’s often happening with digital technology is companies are jumping in to quickly prove AI, machine learning, internet of things, 3D printing, and other emerging technologies without stepping back and thinking about how they impact the broader organization. There is a need to link the digital transformation program with the operational excellence program and invest in training, enablement, and the building of a culture of learning and collaboration to put your team in the best position to achieve your goals.

Make a Strong Business Case

Companies pursuing digital innovation should also be careful not to lose focus on the primary goal, which is to create tools and systems that strengthen their business models. It’s easy to get distracted when you’re out to prove the value of digital enhancements, and you can quickly find yourself in pilot purgatory. In other words, you get so excited about the capabilities of a new tool and how it works that you lose focus on what it can do for your business and, most importantly, for your customers.

It’s analogous to consumers who love technology and are always first in line when a new gadget comes on the market. The new features it offers can be quite alluring. In a business setting, however, you need to stay focused on the job at hand. How does this make you a better company? How does it help you provide a better product? How does it give you an edge over the competition? These are questions that must be answered in order to develop a tool that provides real value.

When we work with clients, we focus on a value-driven methodology that always emphasizes the business case for any project. We assist in building a return on investment (ROI)-led transformation road map that facilitates stakeholder alignment and supports that business case for change.

With an ROI-led approach, we can then focus on proving and scaling value quickly across the enterprise to drive quick wins, build momentum and create a self-funded transformation in many cases.

It’s important to always have the end in mind, even if it shifts or changes substantially through the process. You should have a clear definition of your goals, metrics, and key performance indicators, and define all of the digital enablers that you will need to achieve these objectives. You should incorporate these into your road map. You should also make sure you know what great looks like for your business and bring an MVP-driven approach as you deploy initiatives to drive quick value for your organization.

Harness the Knowledge of Your Workforce

For manufacturers, “individually transferred knowledge” is still widespread, even in the digital age. It’s the master tradesman approach: An individual may have done a job for years and then pass it on to others via formal or informal apprenticeships. This not only keeps the company from more broadly capitalizing on what these experts know, but it also puts the company in the dangerous position of having that knowledge walk out the door as these experts retire.

As the company evolves, there is a need to preserve this institutional knowledge by getting experts to document what they know. However, this approach is not always the most effective or efficient. Take, for instance, the writing of standards. Experts are often asked to develop short written documents that convey how to execute a certain task so that others can benefit from that knowledge. The problem is that it can be difficult to concisely explain an activity comprehensively enough so that it’s useful, but not in too much detail that it might prevent people from actually reading it.

Benchmarking can be a strategic first step to understanding competencies across the organization and can often uncover problems that an organization doesn’t even realize it has.

Furthermore, these subject-matter experts are generally much more comfortable on the floor “turning wrenches.” They’re not technical writers who are accustomed to developing such content during the normal course of their jobs, so it can take them several hours to create single one-page standards documents. The end result: It’s a burden on the experts, who don’t enjoy the task, and not the best use of their time and abilities.

Manufacturers can use digital to more easily and effectively capture and convert this knowledge into institutional knowledge that stays with the company and can be more broadly leveraged across the company. Multimedia platforms are now available that enable workers to easily create instructional content of all kind, and in ways that don’t require the written word. Such platforms feature safe, secure and structured databases that can accommodate a wide range of content, including video, audio, written pieces, webcam images, screen captures and hyperlinks.

Instead of having to struggle for hours writing how to change a part on a particular machine, an expert can record a video of the process in the amount of time it takes to complete the task and upload it to the platform. In our experience, digital tools can reduce the effort to capture knowledge by more than 80% in general, and as much as 95% or more when simple tasks are involved.

Find Your Duality of Growth

Manufacturers must optimize the business of today while innovating the business of tomorrow. This duality of taking steps to extend the lifespan of your current core business while simultaneously leveraging the new growth opportunities of tomorrow is a critical component to building your factory of the future. This is particularly true now more than ever.

In this fast-evolving business environment, organizations recognize that yesterday’s approach to strategy isn’t going to work tomorrow. To mobilize transformative change without inhibiting the current business, organizations need a new, more imaginative framework for developing a future-ready strategy ― one that doesn’t force leaders to negotiate between success today vs. success tomorrow.

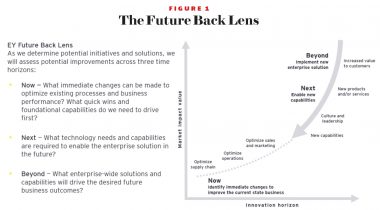

Organizations that embrace and adjust to the duality dilemma in their strategic formulation ― through a future-back approach that situates people at the core; aligns them to purpose, as well as an intentional view of the future, and harnesses a dual-track transformation ― can balance the need for performance today with the need to innovate for a disruptive future (Figure 1).

Data and technology can inform decisions, but it’s people and their insight, creativity and thoughtful analysis that can drive your company forward.

Setting a Vision for Results

There are fundamental reasons that digital transformation efforts fail, yet the most common pitfalls are avoidable by following leading practices. You should start with a clear vision and an objective view of your current maturity so that you can build a realistic road map based on business outcomes and create a link between your digital transformation program and your operational excellence program. People are key, so you should invest in training, enablement, and a culture of learning and collaboration. You should focus on the user experience by using human-centered design thinking and find ways to capture institutional knowledge that can inform decisions and guide your company from where it’s been to where it wants to go.

Data quality and governance are also critical, so you should work to ensure that you add sensors to your equipment to augment data. You need to be agile, which means rapid prototyping with biweekly sprints. While experimentation is important, a first-to-scale approach is key, and quick wins are at the center when building momentum. You should also define a scalable and comprehensive architecture and technology stack and remember that an integrated approach to OT/IT up-front security is critical. Finally, you should co-create and co-innovate with your ecosystem and business partners to help maximize possibilities.

Following COVID-19, it will be even more crucial for the industry to adapt and change to help ensure the factory of the future. Your business needs to be equipped for the now, next and beyond, taking immediate steps to safeguard business continuity and initiate crisis planning while developing a more resilient enterprise going forward. This will allow you to reframe your future, operate in a “new normal,” and transform to succeed. The time to innovate is now.