The Faster Path from Data to Decision

Many manufacturers find that collecting data is no great challenge, but an improper foundation of architecture, governance, and analytics can make it hard to put that data to use.

Data is the thread that runs through virtually every conversation today about the future of manufacturing, from the potential uses of machine learning to the broader capabilities of factories of the future to what the workforce will look like in years to come. Manufacturers generate incredible amounts of data from their internal operations, from their supply chain and from their customers. Harnessing that information effectively is the key to smooth operations, efficient delivery of products and services to customers, and sustained growth.

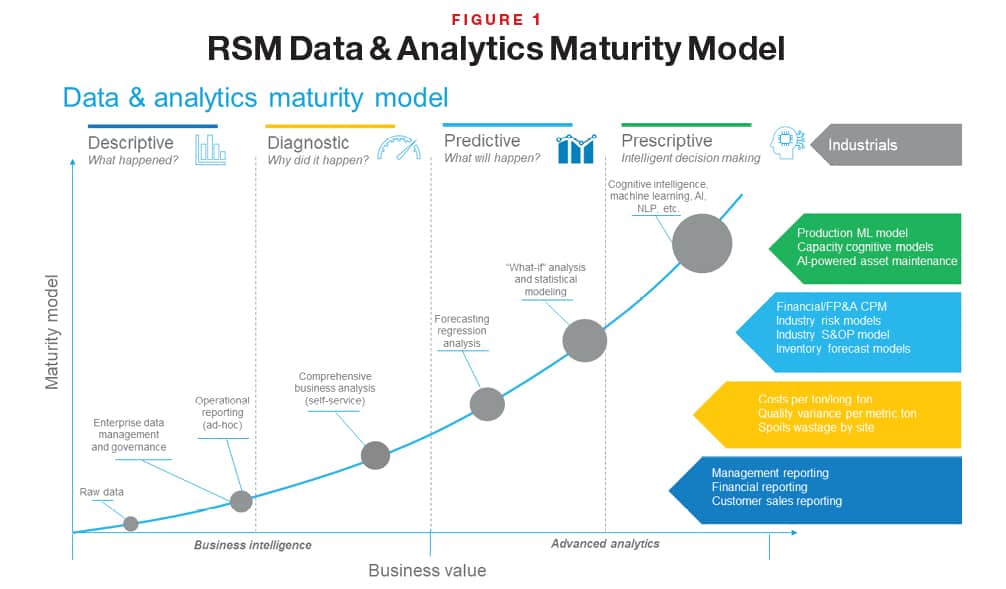

A data-driven organization is one that has moved up and across the data and analytics maturity model (Figure 1). It uses the information that it generates not just to describe what has happened in the business and the world around it, but also to predict what will happen and to have people, systems and processes in place to make automated, intelligent decisions to guide next actions.

However, manufacturers often find themselves unsure exactly what it means to be a data-driven company and feel a lack of clarity around where to focus when it comes to setting themselves up for success guided by data. To be able to take full advantage of the data they generate and collect, organizations need to focus on three foundational areas: data and system architecture, data governance, and data analytics, both traditional and advanced. Senior leadership must make sure that teams across their company share the same business definitions for categories of data and individual data elements to ensure that people and systems can communicate effectively with one other.

Just Having Data Isn’t Enough

Connected devices, customer touchpoints and machines on a factory floor may generate millions of data points, but many manufacturers aren’t using that information to its fullest extent. Having a modern data architecture is a critical part of being able to put that data to use.

Consider, for instance, these two situations:

- Company A has employees who manually collect data into spreadsheets and then review those numbers later to report on the business, identify trends, and make tactical, day-to-day decisions based on their data.

- Company B implements automated processes so that its machines can detect patterns that people wouldn’t easily identify. This allows the business to build a highly detailed body of knowledge about itself and its own performance, and this information can be used from a predictive perspective to plan when machines may need downtime or maintenance.

Both organizations use data to run their business and to make decisions, but could both be considered data-driven organizations? Company B surely has a leg up when it comes to using the predictive power of data to drive greater efficiency and streamline operations.

Companies must be organized and diligent in the way they collect, store and access data, whether that data lives in the cloud, is stored in on-premises servers, is collected from edge devices, or is generated by customers. Having a strategic and well-planned data and system architecture in place enables an organization’s people and technology to build iterative, cumulative insights about whether processes are running smoothly and where there may be room for improvement, where there are new opportunities for growth, and to ensure that there is understanding and transparency across all aspects of their supply chain. The key is that the data—as both inputs and outputs—is interwoven as a holistic part of every business function.

This requires organizations to combine traditional architectures (data warehouses, operational data stores, data marts, reporting, etc.) with newer architectures (cloud, streaming data, data lakes, machine learning, intelligent automation, etc.). Manufacturers should explore the benefits of shifting to cloud-based platforms for computing and data storage if they haven’t done so already. Moving to the cloud not only allows manufacturers to seamlessly scale to meet their growing data requirements but also allows them to take advantage of newer cloud-native architectures and services and to build systems and solutions that were not possible in traditional, on-premises architectures.

“A data-driven organization uses information to predict what will happen and guide next actions.”

Harnessing data in a way that allows the business to predict what’s going to happen next and get ahead of the game is an invaluable asset. Companies that have thought strategically about their data and system architectures and who create a modern, governed data environment will be at a significant advantage to not only become more efficient and increase productivity but to develop new products and to drive growth, competing more effectively in the market.

Good Data Governance is Key to Success

Underpinning the modern data architecture and key to its success is data governance. With such a large influx of information, data becomes decoupled from its sources, requiring organizations to establish processes to effectively manage and govern their data. Proper governance ensures that the definitions and the rules which define shared information are well understood. It establishes organizational, process, and technology enablement standards such that both people and systems have a common understanding of the information they exchange. While these may seem like simple concepts, the lack of a coherent and thorough approach to process and data governance will cost companies dearly over time.

Key pillars of a successful data governance approach, and the program which implements it, include:

- Data quality

- Master data management

- Policy, process, and compliance

- Data security and privacy

- Data stewardship

Organizations that profile, understand, and manage data quality in their enterprise will get predictable results when they use that data for analysis, control, or communication purposes. If they establish the right stewards of transactional data, reference data, and reporting hierarchies, and they build and implement processes and technologies which de-duplicate, merge, and master data from multiple sources, they will all be reading and acting from the same playbook. If companies create the organizational elements to define, agree upon, and implement policy and process with respect to data, and utilize the right tools to administer, secure, and ensure compliance in the use of their data, they will mitigate risk, increase agility and the accuracy of reporting and analytics, reduce costs and inefficiencies, and ensure maximum competitiveness.

Unlocking Value with Advanced Analytics

Data is most useful for manufacturers when they can use this information to map out projections to understand, for instance, when machines might need repairs or to identify issues in the production process. In a similar way, manufacturers can leverage advanced analytics to gain more transparency into their supply chains. This can range from ensuring that their suppliers are meeting organization sustainability targets to identifying gaps in the supply chain that lead to delays in manufacturing and ultimately product delivery to their customers. During the pandemic, this issue was significantly magnified as countries shut down leading to global suppliers struggling to deliver and to meet demand.

Advanced analytics is the key to unlocking these capabilities. While humans might be able to read and interpret data and draw conclusions, advanced analytics uses machine learning to parse through a sea of data and to identify patterns and make predictions that humans are not able to make.

“Lack of a coherent, thorough approach to process and data governance will cost companies dearly over time.”

As organizations move up the data and analytics maturity curve through a modern, thoughtful data and system architecture that embeds governance throughout, they can not only implement advanced analytics but can begin to embed the outputs of these analytics to create automated, intelligent decision-making systems that can increase productivity, reduce downtime and increase growth.

Reaping the Rewards of a Good Data Foundation

Manufacturers are collecting and generating huge amounts of data, and this is going to continue to grow exponentially. However, just having access to this data is not enough for manufacturers to remain competitive and to grow optimally. Manufacturers need to carefully consider and build out their underlying data foundations in order to use the informative and guiding power of their data to its fullest extent.

Manufacturers with a modern data architecture, strong data governance and who use traditional and advanced analytics to good effect are operating at a significant advantage over their competitors that do not. Ultimately, this will allow manufacturers to be more efficient and productive, their performance to be more predictable and sustainable, and the organization will reap the operational and financial benefits for years to come. Those with the commitment and teamwork to implement the critical underpinnings of data-fueled efficiency, awareness, and proactivity will not regret their decision to do so. M