COVID-19 brought a new sense of urgency to digital manufacturing, but M4.0 leadership is still a work in progress, reveals the Manufacturing Leadership Council’s new survey on Next Generation Leadership and the Changing Workforce.

By Penelope Brown

In many ways, the coronavirus pandemic has forced a reckoning with Manufacturing 4.0 and many of its dimensions. In the technology space, it has meant relying on data to help overcome shifts in demand, supply shortages, and, in some cases, the need to institute remote operations. For organizations, it has meant shifting employees’ physical work locations and implementing sometimes complex social distancing protocols at production sites.

For leadership, however, the reckoning may be most pronounced. When the crisis hit, leaders were charged with making decisions for which there was no precedent. They needed to communicate with their teams and colleagues around the clock. They often needed to set up an entirely new infrastructure to keep operations going. Perhaps most importantly of all, they needed to maintain a calm and measured approach at a time of high anxiety, doing their best to ease employees’ fears when they very likely had many fears of their own.

Part 1: Defining the Leadership Role

1 Leadership means data,

collaboration, and integration

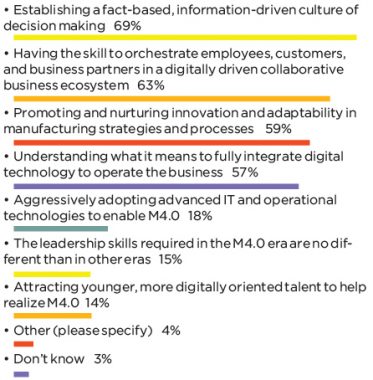

Q: Which statement best describes what leadership means in the Manufacturing 4.0 era?

2 COVID-19 has added urgency to M4.0 investment

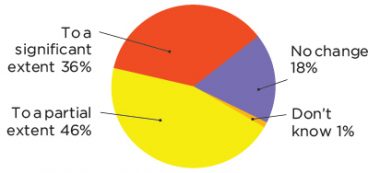

Q: To what extent has the COVID-19 pandemic created a greater sense of urgency about M4.0 digitization within your company’s leadership ranks?

3 Most agree that M4.0 leadership requires a different approach

Q: Please indicate the extent to which you agree with this statement: The emergence of the M4.0 era of information-driven factories will require a substantially different approach and set of skills on the part of manufacturing company leadership.

4 Digital acumen is a leader’s

most important skill

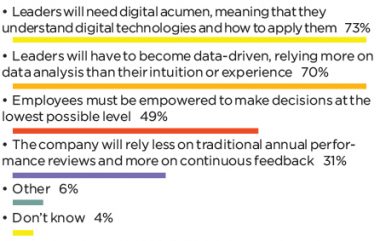

Q: Which new approaches and skills do you feel will be most important for the M4.0 era?

5 Few executive teams have

strong M4.0 knowledge

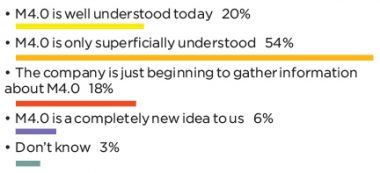

Q: What level of knowledge does your company’s executive management team have today about the concept of M4.0, its requirements, and its challenges?

But when it came to M4.0, a gap that has been in evidence for the past few years between the perceived importance of digitization and leaderships’ ability to manage a digital-first operation came into sharp relief.

This is one of the key findings of the Manufacturing Leadership Council’s new survey on Next-Generation Leadership and the Changing Workforce, one of MLC’s Critical Issues facing manufacturing in the digital era. For purposes of the survey, an M4.0 leader is described as one who establishes a fact-based culture of decision making and who has the skills to orchestrate the enterprise in a digital, collaborative ecosystem. These two competencies have been essential to manufacturers’ response to the pandemic. Anxieties and fears can be allayed with facts and information, and many leaders have said that their digital technologies were indispensable in pivoting operations quickly, and in some cases improved performance even over pre-pandemic levels.

Results from this survey also examine the current state of leadership M4.0 preparedness, the future digital skills that companies will need, the differing viewpoints between operations leadership and executive leadership, and what skills leaders need to build for the collaborative, digital, and always uncertain future.

Most leaders don’t deny the importance of M4.0, but there are sometimes clashes between the C-suite and operational leaders regarding its degree of importance.

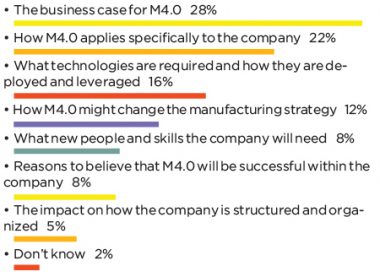

6 Execs biggest question: What’s the M4.0 business case?

Q: What’s the most important thing your company’s executive management team wants to know about M4.0?

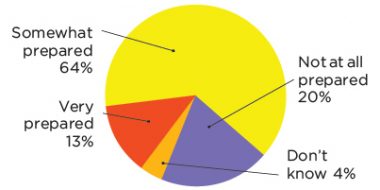

7 Leadership only partially prepared for M4.0

Q: How prepared do you think your company’s executive management team is to lead and manage the journey to M4.0?

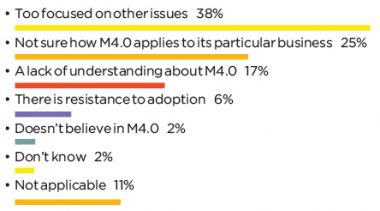

8 Separate issues take focus from M4.0 preparation

Q: If your company’s executive management is not well prepared for M4.0, what is the most important reason why?

9 More than half see success threatened by lack of preparedness

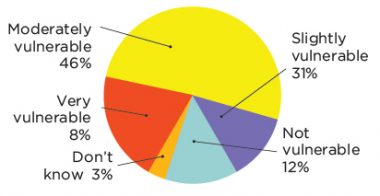

Q: How vulnerable will your company’s future success be as a direct result of your company’s current level of M4.0 preparedness?

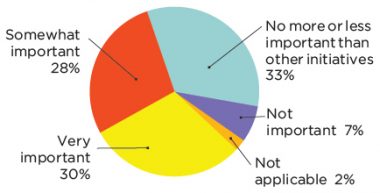

10 A majority of operations leaders cite importance of M4.0

Q: What degree of importance does manufacturing operations leadership attach to M4.0?

A Sense of Urgency

While the pandemic underscored the necessity for the digital factory, the organizational ability to lead and manage a digital-first operation is lagging for many manufacturers. While 82% of respondents said the pandemic brought about a greater sense of urgency about M4.0 digitization at their company to either a partial or significant extent (chart 2), only 20% said that M4.0 is well understood by their executive management team (chart 5).

Additionally, most do not feel that their executive leadership is well prepared to lead and manage the journey to M4.0, with only 13% saying those executives are very prepared (chart 7) and 20% saying they aren’t prepared at all. The most-cited reason for the lack of preparation was that leaders are too focused on other issues (38%) or they weren’t sure how M4.0 applied to their business (25%) (chart 8).

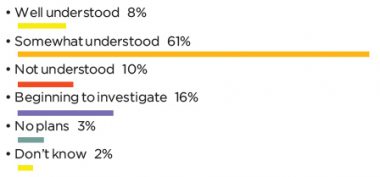

While leaders have a need to develop their own digital knowledge and skills, they also must determine what their future organizational structure will look like and what roles are necessary to fulfill business objectives and goals. That outlook continues to be hazy for the digital future, as just 8% said those roles were well understood at their companies, with most respondents (61%) saying they were only somewhat understood (chart 18).

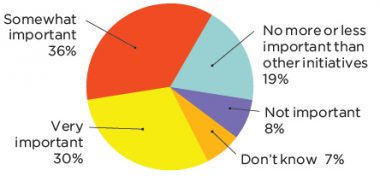

11 Most C-suites believe M4.0 is important

Q: What degree of importance does C-suite business leadership attach to Manufacturing 4.0

12 Many companies lack organizational vision for M4.0

Q: If there is a difference between the degree of importance attached to M4.0 by manufacturing operational leadership and C-suite leadership, which of the following statements best describe why?

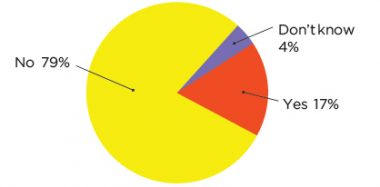

It seems that most companies have an awareness of their needs, but many have not yet done what is necessary to address them. In that regard, 79% of companies have no formal training plan to educate their workers and leaders about M4.0 technologies and skills.

Leadership Quality Check

Many believe that a lack of M4.0 preparedness will be detrimental to future success, with 46% saying their company is moderately vulnerable and 8% very vulnerable (chart 9). The silver lining is that many leadership teams see the importance of digitization; 66% of C-suites believe M4.0 is either very important or somewhat important (chart 11). The same goes for 58% of operations leaders (chart 10).

But what qualities does an M4.0 leader need to have in order to develop, champion, and ultimately usher through to that era of significant digital change? For one, they need to become more familiar with digital manufacturing. Nearly three-fourths of respondents said that leaders will need digital acumen, or the understanding of digital technologies and how to apply them (chart 4).

They also need to walk the talk by leading through the use of data. It’s viewed as important to exercise fact-based leadership, with 70% saying that leaders must become more data-driven and make decisions based on facts rather than experience or gut feelings (chart 4).

Asked to identify the most important M4.0 leadership skill, most said it is the willingness and ability to rethink the business and successfully embrace a digital model (72%), followed by the ability to manage data across the business ecosystem (65%) and use analytics to make data-driven decisions (65%) (chart 13).

Part 2: Developing Knowledge and Expertise

13 Embracing a digital model is essential to success

Q: Looking ahead, what degree of importance would you assign to the following M4.0 leadership skills and abilities?

14 Data analytics, cybersecurity are top areas of emphasis

Q: Looking ahead, what degree of emphasis would you place on the following technology areas in terms of developing knowledge and expertise?

Part 3: Assessing Leadership Challenges

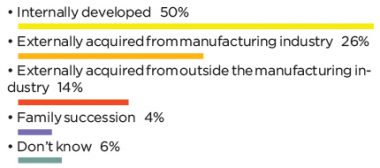

15 Most see future leaders already in the company

Q: Where do you see the next generation of leaders coming from for your company?

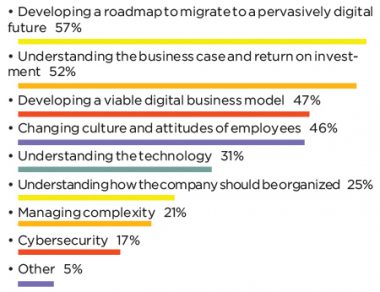

16 Digital roadmap, business model are top leadership challenges

Q: In thinking about the requirements and implications of M4.0, what do you think are the most important challenges for leadership?

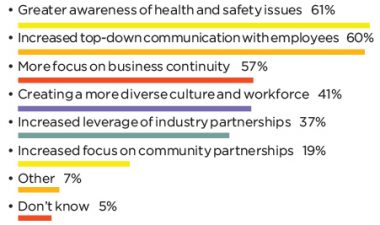

17 Safety, communication emerge as new leadership priorities

Q: How have recent events changed leadership skills and behaviors for the future?

Part 4: Workforce Development and Transition

18 Necessary digital roles only partially understood

Q: How well prepared do you think your company is in understanding the new digital roles and skills that you will need in the next few years?

19 Most companies lack formal M4.0 training plan

Q: Does your company have a formal training plan to educate workers and leadership around the requirements of M4.0?

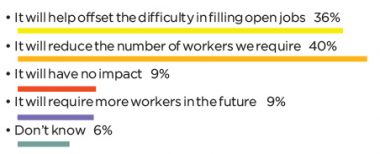

20 Automation aids in filling chronic worker shortages

Q: What impact do you think the increasing adoption of automation and advanced M4.0 technologies will have on workforce levels in your company in the future?

C-Suite vs. Operations

Whether at the operational or C-suite level, most leaders don’t deny the importance of M4.0. But some companies see a clash between those groups on the degree of importance. For 35%, development of an overall digital vision and strategy is still a work in progress and accounted for some of the differences (chart 12). A third said that tactical operational accomplishments had been achieved with M4.0, but those had not yet been scaled to the enterprise.

Indeed, the need to develop a technology roadmap was the most-cited challenge to leadership (chart 16), with 57% saying it remains a hurdle. Others said there was a need to understand the business case and return on investment (52%) and also to develop a viable digital business model (47%). The workforce factors in as well, with 46% saying it is necessary to change the business culture and attitudes of employees.

M4.0 leaders are charged with both improving their own digital acumen and leading through data and fact-based decision making.

COVID-19 and Leadership

If you ask any manufacturing leader about their experience over the last several months, you’re likely to hear things like “never would have believed it,” “biggest challenge of my career,” “once in a generation scenario,” “life-changing.” It’s undeniable that the pandemic crisis and other recent events have made an immense impact on leaders and what they will be taking with them into the future.

Most say that they now have a greater focus on health and safety (61%), increased top-down communication with employees (60%), and more focus on business continuity (57%) (chart 17). Others are thinking of how to improve diversity at their organizations (41%) or how to leverage their industry partnerships (37%) and community partnerships (19%).

It’s unlikely that much of business will return to what we knew as normal prior to the pandemic. What goes and what remains is yet to be seen. But steeped in a crisis they never could have conceived, leaders are now armed with a new set of lessons and skills that are likely to serve them through the future, in good times and bad. The pandemic has accelerated the timeline for the digital factory. Now, it’s time for leadership to catch up. M

Survey development was led by Penelope Brown, Content Director, with input from the MLC editorial team and the MLC’s Board of Governors.