The MLC Elects New Chair, Vice Chair and Two Leading Industry Figures to its Board of Governors

The Manufacturing Leadership Council (MLC), the digital transformation arm of the National Association of Manufacturers (NAM), has announced the election of new leadership for the MLC Board of Governors for 2024. Additionally, two leading figures from industry have been elected to join the Board. The MLC is the nation’s foremost executive leadership organization dedicated to helping manufacturing companies transition to the digital model of manufacturing by focusing on the technological, organizational, and leadership dimensions of change.

Two long-serving board members have assumed new leadership roles. Dan Dwight has been elected as the MLC Board of Governors Chair. Dwight is President and CEO of Cooley Group and a member of the NAM Executive Committee and Board of Directors. Meanwhile, the new Vice Chair is Ron Castro, Vice President and Chief Supply Chain Officer at IBM Corporation.

Joining as new members of the Board of Governors are Dan Dralle, Executive Director US Government Affairs and Global CIP at Nexteer Automotive, and Larry Megan, Head of Digital at Baldwin Richardson Foods.

“We are very fortunate to have Dan Dralle and Larry Megan join the MLC Board of Governors,” said David R. Brousell, MLC’s Founder, Vice President and Executive Director. “Under Dan Dwight and Ron Castro’s leadership, the Board will vigorously pursue its mission of keeping MLC in the forefront of Manufacturing 4.0 leadership with renewed commitment and energy.”

As an advisory body, the MLC Board of Governors provides guidance to the MLC on its Critical Issues agenda, research studies, and its programs and services for the MLC membership.

“The MLC is leading the manufacturing digital transformation charge,” said Dan Dwight, new Chair. “The Board of Governors keeps its finger on the pulse on what’s happening in factories and connects the dots to technology partners and academia so MLC members can forge a path to a more resilient future for manufacturing.”

With these appointments, the MLC Board of Governors now consists of 18 industry thought leaders who represent the full spectrum of industries and functional roles including large global enterprises, small and medium-sized manufacturers, leading academic institutions and a full array of areas of expertise.

Board members whose terms expired or who have retired include immediate past Board Chair Mike Packer, Eric Fidoten, Brad Heath, Krishna Srinivasan, and Bart Talloen.

Crystal Ball: Business Resilience in 2030 and the Digital Dexterity Effect

Digital transformation is today’s tested and proven path to business resilience. We help manufacturers digitally transform to strengthen their resilience every day. But our era is defined less by permanence than by alacrity of adaptation. Manufacturers must already evolve their approach to business resilience to remain competitive.

Granted, the need for this evolution is neither intuitive nor obvious. And in fairness, resilient manufacturing enterprises in 2030 will look much like such enterprises do today. But the means for achieving and sustaining resilience by decade’s end will be radically different. Here’s why, and how to prepare for it.

Why business resilience will be different in 2030

Resilience describes a business’s ability to adapt to change effectively and efficiently. For many reasons, data-driven manufacturers are indeed able to adapt well. That’s why businesses that aren’t already data-driven are becoming so.

But digital transformation is a continuum. And few companies believe they have done all they need to do in their transformation. Most recognize that they are in the early or intermediate stages of digital transformation. That will change.

By 2030, businesses that lead their industry will have passed beyond the stages of digital transformation. The businesses will have entered a state of digital dexterity. In that state, business resilience manifests in sharply different ways than it does today.

How business resilience will be different in 2030

Business resilience based on digital dexterity has many facets. Among them, three stand out as being potentially unexpected. First, high-level objectives will remain vital to defining initiatives aimed at strengthening business resilience. But those objectives will not be the exclusive driver. Digitally dexterous manufacturers will employ a fluid governance model. This reflects the future reality wherein company-wide resilience initiatives will emerge from diverse organizational levels, and not always from the top.

A second difference in the way business resilience will manifest lies with the workforce. Digital dexterity means making sure that the workforce has access to, and understands how to use, your business’s data and technologies. Employees will have the information they need to understand how changing their own workflows could have wide-reaching benefits. They will be able to see ways to boost resilience from their specific position. These will be ways not obvious from a top-down view.

In fact, the top-down view will itself be different, which is the third key facet we are considering. Digital dexterity will mean that all executives – not just those in IT – feel at home with technology. In the same way that an executive today can assess how well one staff member is performing, they will be able to assess how well a technology is performing. For example, is a particular AI algorithm doing what it should, and is it enabling the desired business resilience outcomes? That level of digital literacy will be a basic requirement for leaders in digitally dexterous companies.

What you can do now to prepare for the future of business resilience

We’ve called out ways of enabling business resilience in the future that will be strikingly different. Preparing for those differences will set you on the right path. A cultural awareness and acceptance of shared responsibility for business resilience takes time to develop. But it also follows naturally as your workforce evolves on the path to digital dexterity. The key here is to ensure that everyone in your organization has the opportunity to participate in the digitization of their roles. Organizational change management will be instrumental in this workforce development.

Establishing a higher baseline of digital literacy among your leadership team takes time as well, and you’ll need to begin soon. Leaders must be able to evaluate technologies for their effectiveness as intuitively as they do employees, but that is predicated on educating and training leaders with the requisite skills. Ideally, upskilling and reskilling should always remain slightly ahead of technological change.

Business resilience in 2030 will be decentralized and deeply integrated in the manufacturing enterprises’ people, processes and technologies. It will be the inevitable outcome of your organization’s digital dexterity.

To learn more, please visit NTT DATA’s manufacturing page.

About the Author

Siva Gurupackiam is Senior Vice President of Manufacturing Industry Solutions at NTT DATA.

Siva Gurupackiam is Senior Vice President of Manufacturing Industry Solutions at NTT DATA.

Digital Leadership – An Imperative for Manufacturing 4.0

Improving people-centric leadership, psychological safety and intergenerational dynamics drive digital transformation forward

Digital transformation has been around as long as I have been in the workforce. The depth, capabilities and reach of technology has vastly grown, but the reality is we have been working on digital transformation for decades, in all industries and all capabilities. Yet, with all this experience, the percentage of digital transformations that fail continues to hover at around 70%, a dismal number[1].

Digital transformation has been around as long as I have been in the workforce. The depth, capabilities and reach of technology has vastly grown, but the reality is we have been working on digital transformation for decades, in all industries and all capabilities. Yet, with all this experience, the percentage of digital transformations that fail continues to hover at around 70%, a dismal number[1].

Today, we are bringing some of our latest technologies in IoT, big data and analytics, and artificial intelligence into the industrial space with vast opportunities in efficiencies, quality improvement and increased safety. It is an exciting time for manufacturers and the stakes are high. However, as Manufacturing 4.0 technologies offer enhanced efficiency, manufacturing leaders are faced with both new and old challenges while implementing these new systems and processes. How can we improve on that 70% failure rate? Is digital transformation different on the shopfloor? How do I get everyone on board?

A digital leadership approach is key to achieving Manufacturing 4.0. It extends beyond the processes and technology. It requires taking a people-centered approach throughout the organization, creating a culture and atmosphere that drives resilience, agility and innovation, and encouraging participation and open communication at all levels of the organization.

The events of the last few years have shown that people are critical to manufacturing operations, even in our digital future. Manufacturers who successfully achieve their adoption of Manufacturing 4.0 technologies will have done so by engaging their leaders and employees and enabling organizational participation from top to bottom. They will have employed digital leadership.

What is Digital Leadership?

At its core, digital leadership involves leading through disruption and transformation, harnessing digital technologies to achieve organizational objectives. It calls for an understanding of emerging digital technologies and the ability to guide their integration into existing processes. But underpinning this is your employee base who must adapt to the fast-paced changes driven by technology. An even more critical key to any transformation’s success, these employees must understand the inner workings of the organization. A digital leader must foster an environment that encourages participation, drives agility and resilience, and rewards innovation at all levels of the organization. It is critical this leadership approach extend beyond the executive suite and managerial roles all the way to the front-line supervisors. Digital leadership focusing on the people first is key to achieving a successful transformation.

What Skills Do Your Leaders Need?

Effective leaders in the digital age are not just those in the C-suite. They are individuals across the organization who champion innovation, collaborate across levels and functions, and prioritize continual learning. that looked at leadership styles and their success during the COVID disruption, leaders using a coaching style had teams that were more resilient, engaged and productive[2].

We will call this digital leadership, and there are a few key skill sets that make digital leaders so effective in driving transformation through a manufacturing environment.

- Communication – Many change management programs focus on outward communication, informing about and justifying change. However, a strong digital leader focuses on active listening and curiosity. Through this type of communication, issues, concerns and blockages will be found earlier and resolved sooner.

- Conflict Resolution – There will be many conflicts that arise in any digital transformation. A successful leader ensures that respect for all parties is the basis upon which any conflict is addressed and resolved. By insisting on and modeling respect first, a leader shows each person they are valued and encourages issues to be brought forward.

- Accountability – Leading by example and doing what you say builds trust. Trust is one of the hardest things to build when introducing new processes and technologies. A digital leader is aware of their words and actions and acts in a way that builds trust.

- Self-Reflection/Vulnerability – Digital leaders have learned to embrace the uncomfortable. They acknowledge their own feelings and are open to where there may be gaps in the transformation program or their own knowledge. It is very important that digital leaders do not feel like they have to be the ultimate experts. A strong digital leader conducts a consistent self-reflection on the program and progress and is open to bringing in outside experts when needed.

- Empathy – A strong leader spends time noticing the people in the organization. They look for who is speaking up and who is quiet. They engage and seek to understand both types of people. In times of disruption, your biggest distractors will not actively speak to you as the leader. It is important to engage every member of the team to bring everyone along and find issues at the place and time they arise. This need for empathy at the individual level is why digital leadership must span the organization, from executive to front-line leader. Leaders must actively involve and include team members, understanding their motivations and aligning individual strengths with organizational goals.

Why Take a People-Centered Approach?

Manufacturers do not run without people. The people in your factories and central offices deeply understand the business and will be on the front lines of adopting the digital changes. In some cases, they will be contributing to the technology itself by supplying the knowledge and input needed for AI and ML models. In all cases, the people running the manufacturing lines will have a front-row seat into the impact and success of any technology implemented. It is critical that these employees and leaders feel comfortable voicing their concerns, sharing ideas and taking calculated risks. By taking a people-centric approach to digital transformation, organizations can tap into an enormous well of knowledge, support and energy to help drive the program’s success. On the contrary, if a command-and-control approach is taken, people will distrust the transformation, issues will not be reported, and innovative ideas will be silenced.

Psychological Safety – the Key to Success

Psychological safety refers to an environment where employees feel comfortable, secure and confident in expressing their opinions, concerns, ideas, and identifying mistakes without the fear of negative consequences. Creating a culture of psychological safety is critical in a manufacturing environment where safety, quality and efficiency are paramount. Considering the added complexity of a Manufacturing 4.0 transformation, building a culture of psychological safety can be the difference between success and failure.

Creating and maintaining psychological safety in manufacturing requires proactive efforts from leadership, clear communication channels, training programs and a commitment to address issues without blame or retaliation. When psychological safety is prioritized, employees are more likely to engage in the ongoing process of identifying and mitigating risks, ultimately contributing to a safer, more efficient, and higher-quality manufacturing operation and a successful digital transformation.

Some of the key components of a psychologically safe manufacturing environment that should be employed throughout the organization:

- Open communication is modeled and fostered

- Failures and learnings from mistakes are openly discussed with no blame

- Raising concerns or issues is celebrated and retaliation is not tolerated

- New ideas are considered and encouraged

- Employees feel comfortable expressing well-being concerns with leadership or HR

Fostering a culture where individuals are encouraged to voice their opinions or concerns and learn from their mistakes is essential. It will not only improve operations during the transformation but for the long haul as well.

Navigating Intergenerational Challenges

Today’s businesses encompass a diverse range of generations, from Generation Z to boomers and much has been made about intergenerational dynamics, particularly when it comes to digital participation. You could probably fill a library with the amount of material written on how to engage each generation, what they care about and how they work. With all of this noise, there is a strong risk that we make assumptions based upon generational classification. As leaders, we must understand how to manage intergenerational dynamics effectively, but at the same time challenge stereotypes and focus on each person individually with empathy and respect.

Baby boomers or Generation X have likely grown up in more of a command-and-control leadership environment which tends to minimize psychological safety. Yet, these more experienced employees also tend to possess invaluable experience and institutional knowledge that you do not want to lose, so building trust through empathy, respect and active listening will be critical to helping this persona be an active participant in the transformation. Building an inclusive environment invites this generation to contribute their experience, transferring know-how to the digital framework and to newer employees.

Younger generations, such as millennials and Generation Z have grown up in more of an open, collaborative environment where information is democratized and individuals have more power. Open communication, active listening and authenticity will be critical for this generation.

Although different generations might have varying approaches and motivations, it is critical that leaders avoid making stereotypical assumptions. Creating an inclusive environment where everyone’s voice matters and everyone is valued will create thriving intergenerational teams

Front Line Leaders are the Key to Success

Front-line leaders (or shopfloor leaders) are normally the newest leaders, have the largest span of control, and touch the largest section of the organization. Yet, these leaders are often not considered critical to a Manufacturing 4.0 transformation. Successful digital leadership expands to all levels of the organization. Since our front-line leaders touch such a large section of the organization, their impact must be considered and encouraged. Here are some ideas:

- Educate these leaders on the transformation’s goals and be open about timelines and changes.

- Actively listen to this leadership level on a regular basis taking their input and ideas into the program. Coach them to do the same with their teams and share that feedback up the chain.

- Supply adequate leadership training and ensure their leaders are modeling those skill sets critical to driving agility, resilience and innovation.

Having all levels of the organization acknowledge front-line leaders as key to a transformation’s success will support a positive outcome.

Digital Transformation is a Team Sport

The art of digital leadership lies in striking a balance between technological innovation and people-centric leadership. But this responsibility does not sit with one person or even a few. Each layer of the organization will be critical for success in both aspects. As organizations undergo digital transformation, it will be critical to supply leaders from the executive suite to the shopfloor guidance and resources needed for success. By fostering a culture of psychological safety, valuing intergenerational perspectives, and embracing employee input and dissent, leaders will build cohesive teams that trust one another and feel a sense of belonging. This will lead to better problem-solving, greater innovation and overall productivity – all critical for thriving through disruption.

Conclusion

Digital disruption and transformation have reached the shopfloor. The combination of IoT, big data and analytics, and artificial intelligence will drive significant improvements in quality, efficiency, safety and energy use. How quickly and extensively a manufacturer can get there will affect everything from that organization’s competitiveness to regulatory compliance. This era of rapid technological advancement requires manufacturing leadership to evolve. It’s not just about knowing how to leverage the latest tools; it’s about knowing how to empower, inspire and guide teams toward a future where technology and human potential intersect seamlessly. Employing this people-centric, digital leadership approach to transformation will provide a lift and accelerant to any Manufacturing 4.0 program.

As industries continue to change, it’s these digital leaders who will navigate the complexities of digital transformation, engage their employees in embracing the change, and propel their organizations to new heights.

About the Author:

Diane Guganig, an experienced Strategic Advisor and Sales Executive at Hitachi Digital Services, began her tech obsession at age five after touring a room-sized computer. Starting as a systems engineer, she spearheaded software development initiatives, led teams, and played pivotal roles in resolving significant business challenges. Transitioning to sales allowed her to partner with and solve a wider number of challenges, including intricate cross-industry issues. Her passion for technology has evolved into a mission to enhance the human experience, leading her to partner with purpose-driven enterprises dedicated to solving real-world problems for a better future.

[1] McKinsey: https://www.mckinsey.com/capabilities/people-and-organizational-performance/our-insights/successful-transformations

[2] https://www.betterup.com/blog/coaching-during-crisis International Journal of Evidence Based Coaching and Mentoring 2022, Vol. 20(2), pp.3-19. DOI: 10.24384/ektn-xx15

The Surprising Keys to Manufacturing Digital Transformation

From IT and HR to finance and leadership, the keys to successful digital transformation lie in a cross-functional approach

Few would argue that automation and digital transformation (DT) are not critical to the future of industrial automation. According to Gartner, 80% of manufacturing CEOs are increasing investments in digital technologies — led by artificial intelligence (AI), Internet of Things (IoT), and data and analytics — to counter economic pressures and to drive growth and profitability. Meanwhile, a 2023 MLC survey of manufacturing leaders indicates that 85% see an increase or no change to their companies’ Manufacturing 4.0 investment despite economic concerns.

And yet Gartner reports only 8% of industrial organizations say their DT initiatives are successful.

Eight percent?

It is a dismal number. Why so few?

It is tempting to pin the blame on technology snags. But technology is rarely the issue. Most organizations nowadays are engineering-led. They tend to jump on new technology right away. It’s cool and fun, and the solutions typically are readily available in the market.

Digital transformation initiatives in manufacturing fail because of organizational readiness. Or more specifically, the lack thereof.

To be clear, both organizational readiness and technical readiness are critical. But companies are generally better off when it comes to technical readiness due to the aforementioned reasons, and because they have a history of technology investments and the requisite skilled workers. With that as a backdrop, we advise industrial manufacturers to adhere to the following best practices when implementing digital transformation initiatives, with a particular emphasis on managing various organizational readiness issues, which span from the cultural to the financial.

Digital transformations should be cross-functional — but led by manufacturing operations

Digital transformation teams should be cross-functional, with representation from manufacturing, engineering, supply chain, and material operations. But cross-functional DT teams should be led by manufacturing operations. Why? Because manufacturing ops understands the floor — specifically, the problems on the floor and how to drive value.

IT is partner #1

Manufacturing operations and IT have to work hand-in-hand, with IT responsible for reliability, security and data — the latter of which is obviously the fuel for data-driven manufacturing. There are several best-practices specifically when it comes to the data.

- Data must be centralized so that the entire organization is working off of one source of truth.

- Data should be collected according to the problem you are trying to solve. Data isn’t free, so you do not need to collect it all. Start with the problem on the manufacturing floor, and let that dictate the data you collect.

- Data should be driven down to the appropriate people to make the appropriate decisions. Think through any data user — operator, team leader, quality leader, maintenance leader — and their standardized work. Then design your system to get the correct data in their hands for their jobs. (We will come back to some of the implications of getting this wrong.)

Don’t forget HR

HR support is critical in a few regards. First, HR can lead on the critical task of bridging the gap between newer, younger employees and older employees. Our workforce is transitioning and changing, and we are getting many new employees who have a great understanding of the technology and who bring new ways of thinking. At the same time, we have our older workers – I often refer to them as our “oak trees.” They really know how the floor runs and how it operates. Companies need both, and both can learn and benefit from each other.

HR’s other critical role is bringing team leaders and operators on the floor along on the journey. People will have concerns with any DT initiative. Will I get left behind? Is this going to replace me? Is Big Brother watching me? From day one, companies need to engage the floor — operators, team leaders, quality operators, maintenance operators — and make sure that they understand why the company is bringing technology in, the purpose, and how it is ultimately going to make their lives better and their jobs easier.

Be realistic about finances

Digital transformations are often under-capitalized. Ongoing costs are overlooked. Companies need to carefully account for expenses like ongoing maintenance costs, integration work, data collection and potential downtime. Many of these add-on costs aren’t properly captured in the budgeting process and later bite companies during implementation.

Leadership must protect the culture and drive decentralized data-driven decision-making

Leaders must embrace the transformation and ensure that digitization doesn’t degrade or destroy company culture.

First, leaders should never allow “data hoarding” at the top of the company, falling into the trap of thinking, Now I can solve all of these problems myself. Empower the right people with the right data to do their jobs. Problem-solving and continuous improvement should advance as long as data is being drive down to the right level of the organization.

Second, leaders must bring the operator along on the journey so they understand why the organization is making changes. This is similar to HR’s role mentioned above, but the questions that leaders answer are different. Why a wearable? How are these changes going to make me more effective and my job better? Leaders must not only manage the change — they have to inspire the workforce in the process.

Ultimately, company leaders should ask themselves, How do I make sure that we stay true to the philosophies that we learned from the Toyota Way — Kaizen and Genchi and Genbutsu … teamwork, respect and challenge? Culturally, nothing really has to change in the digitized world. The key is staying true to the philosophy of operator and team leader first, while driving data-driven decision-making throughout the organization.

About J.R. Automation

JR Automation, a Hitachi Group Company, partners with industrial manufacturers all over the world to design, build, and integrate advanced automation solutions — from assembly automation, dispensing, and vision systems to process design, controls engineering, and software integrations. We have built custom technology solutions for every application, process and industry, and helped ensure our customers were organizationally ready for the change.

About the Author:

Mike Lashbrook is Vice President Digital Solutions and Senior Vice President, M&A Connected Industry, JR Automation, a Hitachi Group Company.

AI Driven Solutions for Manufacturing Excellence

Thanks to the rising ease of adopting cutting-edge technologies like artificial intelligence, Internet of Things (IoT), big data analytics, and robotics, manufacturing is booming across the world. In the United States, for instance, a manufacturing boom has swept across the country in the last two and a half years, with the South and Mountain West having especially strong growth, according to Bureau of Labor Statistics (BLS) data1. The U.S. economy has added some 800,000 manufacturing jobs nationwide in just the last couple of years. In terms of numbers, Texas is the top state for new manufacturing jobs, with 86,000 new positions, from January 2021 to May 2023, according to BLS data. Next comes California with 79,000 jobs; Florida with 37,000; Ohio with 31,000; and Georgia with 29,000. Nevada had the greatest percentage increase at 15%, followed by Montana at 11% and Wyoming at 10%.

Manufacturing has never not been a strong suit of the U.S. In fact, the country produces 40% more factory output today versus 20 years ago, but with 5 million fewer workers, per the American Enterprise Institute2. In 2017, the U.S. produced about four times more factory output than in the 1940s with about the same number of factory workers, which is around 12.5 million! The “culprit,” if any, has been automation, including advances in technology and the rising productivity of U.S. factory workers.

New, smart manufacturing investments provide a perfect opportunity to build (back) smarter and stronger. Manufacturers now are unlocking new levels of efficiency, productivity, and competitiveness as they quickly adopt automation and digitalization. The combined power of OT and IT DataOps and domain-specialized AI and ML models is enabling manufacturers to unlock new levels of efficiency, productivity, and competitiveness. However, there are challenges to overcome on the path to realizing the full potential of smart manufacturing. In this article, and based upon the discussions we had at the recently held MLC Rethink Summit, we will explore some strategies to overcome these challenges and drive enterprise-wide transformation.

The adoption of advanced tools, solutions and processes in smart manufacturing is gaining traction across industries. It is projected that the global smart manufacturing market will grow from $297.2 billion to $787.5 billion by 2030, at a compound annual growth rate (CAGR) of 14.9% (source: Grand View Research). According to MarketsandMarkets, use of AI in the manufacturing market is projected to reach $16.7 billion, at a CAGR of 47.9% from 2022 to 2027. These figures highlight the immense business value of smart manufacturing practices.

What are some of the biggest obstacles that manufacturers face when it comes to unleashing full-scale digital transformation? Broadly speaking, they fall under the themes of legacy products and infrastructure, change and people management, and needing expertise that spans IT-OT data integration, analytical modeling and data management. Let’s take a closer look at each.

Product Legacies

One of the key challenges in scaling smart manufacturing initiatives is the complexity of integrating diverse systems and technologies. According to Deloitte, 44% of executives identified legacy systems as a barrier to implementing advanced solutions. Modern manufacturing environments are complex mixes of disconnected systems that do not communicate with each other. This lack of interoperability hampers data sharing and insights, preventing organizations from harnessing their full potential and measuring ROI. A Frost & Sullivan survey revealed that 79% of manufacturers face challenges in integrating legacy systems with new technologies. To overcome these, companies need to invest in a robust digital infrastructure that can seamlessly connect and integrate various systems.

Change Management

Change management is a critical factor that can and has sunk many smart manufacturing digital transformation projects. Years of experience working with multiple stakeholders in a manufacturing organization has revealed a near unanimous conclusion: if everyone in an organization is not onboard with clear expectations and benefits caused by the changes brought on by digital transformation, initiatives will fail.

Let’s consider change management inside the realm of dynamic scheduling. Much of industrial scheduling is reactive, where the shop floor adjusts to complete work as it comes in. Dynamic scheduling is proactive, with the schedule being adjusted to maximize production. A dynamic scheduling system adjusts production to minimize resource issues (like machine breakdown, tool failures, quality issues) or job-related (rush jobs or cancellations), and ensures optimal use of shop floor resources. Here’s an example where dynamic scheduling failed due to an overlooked human element (change management). A manufacturer had undergone a major investment in a dynamic scheduling system that failed to yield results. The change required employees who worked on a particular assembly line to swipe in to start work at their station. There were no incentives provided to workers that explained the need to swipe in because they had already swiped in for their shift at work. Since they were not on board with the value of this extra step, the system didn’t work and was abandoned.

Obstacles can abound, but a careful analysis of changes to all stakeholders can help sustain a digital transformation process.

Technologies like Predictive Maintenance (PdM) and Quality Control

Traditionally, manufacturers use reactive maintenance, fixing equipment only when it breaks down. By leveraging AI/ML-driven algorithms, including analyzing historical data, manufacturers can predict and prevent equipment failures before they occur. These algorithms can identify patterns and anomalies, enabling manufacturers to schedule maintenance proactively, optimize spare parts inventory, and minimize unplanned downtime. PdM also prevents waste by precluding the need for unnecessary maintenance.

Another key application of AI and ML is quality control. AI and ML algorithms can be trained to analyze vast amounts of data, including images, sensor readings, and production parameters, to detect defects and anomalies in real-time. By automating inspection processes, manufacturers can achieve higher accuracy and consistency while reducing the need for manual inspection. According to a study by Capgemini, AI-based quality control systems can reduce the cost of quality by up to 50% and increase productivity by up to 25%.

However, choosing the right technology partner is crucial to success. PdM and quality control are two areas where plenty of tools and providers exist, but few have found repeated and large-scale success. In reality, digital industrial transformation is a very high-touch activity: it takes much more than a software product or singular service that enables long-term, repeatable success. It takes a bridging of the IT, OT and business operations worlds with a portfolio of factory hardened industrial IoT solutions, versatile and easy-to-use software products, and professional system integration and advisory services and support.

Secure IT + OT Data Systems

As the use of IoT, analytics, digital twins and other advances facilitated by better gleaning of insights from contextualized IT and OT systems data proliferates, their impact on smart manufacturing is becoming more profound. However, continued success of AI and ML requires a wholesome approach, including investing in talent, data infrastructure, and robust OT cybersecurity. As more connected devices gather larger amounts of data, implementing robust cybersecurity measures to protect information needs to be a focus.

The risks are high. According to IBM, 61% of cybersecurity incidents at OT-connected organizations last year were in the manufacturing industry. Implementing strong cybersecurity and establishing strong governance frameworks are essential to protect sensitive data. This includes implementing strong access controls, encrypting data, updated software and firmware, and conducting rigorous vulnerability assessments. Establishing a strong governance framework to define policies and procedures for data handling, storage, and sharing is critical.

By utilizing secure AI-based edge computing and optimized multicloud adoption, manufacturers can create a unified, scalable ecosystem where data flows seamlessly and securely throughout the organization and its stakeholders.

The Experienced Leadership Difference

Since leading the Industrial IoT charge from its earliest days, the best providers in the industry, like Hitachi Vantara, have learned a few things. From hundreds of IoT projects deployed globally in manufacturing, energy and transportation sectors, they’ve witnessed that IIoT projects erase IT and OT data boundaries, and are almost always transformational, high-touch affairs. The truth is, no two customer projects are the same. Successful, scalable, repeatable, data-converged, edge-analytics-enabled delivery requires a trifecta approach – expertise and availability of three critical factors including:

- Industry-specific AI/ML-based solutions and models

- Tried-and-tested templates and accelerators that are secure and repeatable and can run where required, and

- World-class ecosystem of group companies and a strong partnership expertise to deliver it.

That is what customers need: not just tools and software, but the ability to put it all together and bring it home for their business outcomes.

Consider the use case of Logan Aluminum. Over the past six years, Hitachi Vantara has worked with their plant in Kentucky to bring the optimal benefits from insights derived from the 4M sources of data: hu(m)an, Machines, Methods, and Materials. By definition, these data sources are from IT and OT sources. IT data examples are employee information, their training details, experience and expertise levels, clearances for different areas of the factory, shift information, management information and backup personnel, PPE use depending on the day’s shift or task, etc. Material and method data sources can include tags from databases that hold information on orders, suppliers, supplier quality, stock and lot codes, shipment and inventory on hand, and more. OT sources are asset and machine data: pressure, vibrations, temperature, oil viscosity levels, date of last service, and the how/what/when/who associated with past repairs, and hundreds of others.

Working within the customer’s existing processes and with their systems, 500,000 tags/second are organized and collected and ETL’d (Extract-Transform-Load) into a data warehouse of their choice, both on-premises and in their cloud vendor’s systems. Countless possibilities of combinations on these yielded information that helped the customer improve quality, energy efficiency issues, enhance safety indices, shift from scheduled to predictive maintenance, optimize coil rolling and finished goods handling, and many more.

With hundreds of vendors and platforms and solutions around, customers need expert guidance on integrating digitized edge technology with their IT backend quickly and cost-effectively more than ever. Hitachi Vantara combines OT DataOps capabilities – knowledge and experience in managing, handling and analyzing OT data – with software products, IT best practices and consulting-through-implementation offerings that are applicable to operations, IIoT-based accelerators, data catalog and ETL/ELT platforms, and versatile reporting dashboards that are customizable for multiple persona.

Conclusions

Smart manufacturing is new manufacturing, a crucial driver of industrial success, with the global market projected to reach $787.5 billion by 2030. Overcoming integration challenges and investing in a robust digital infrastructure are essential to enable seamless connectivity and getting real-time insights. Change management is a significant hurdle in sustaining smart manufacturing practices, so organizations are addressing it by spending more time in articulating the value for all involved stakeholders earlier. Data security is a high priority, and strong cybersecurity measures and governance to protect sensitive information and build trust are essential for success and getting out of “pilot PoC purgatory”.

Customers need long-term partners that invest to understand their pain points from multiple viewpoints, offering secure, verticalized edge-to-multicloud solutions, templates and best practices to help them successfully and repeatedly achieve their high-touch digital transformation objectives.

1 https://www.axios.com/2023/03/07/us-manufacturing-growth-outpaced-world

2 https://www.aei.org/carpe-diem/the-us-produces-40-more-factory-output-today-vs-20-years-ago-with-5m-fewer-workers-technology-job-theft/#:~:text=The%20US%20Produces%2040%25%20More,Ago%20with%205M%20Fewer%20Workers.

About the Author:

Shamik Mehta is the Director of Industrial Digital Services at Hitachi Vantara with 25 years of experience in IIoT, AI/ML-based data analytics, semiconductors, renewable energy, and e-mobility. He specializes in thought leadership for technology applications in smart manufacturing, energy, and electrified transportation.

Shamik Mehta is the Director of Industrial Digital Services at Hitachi Vantara with 25 years of experience in IIoT, AI/ML-based data analytics, semiconductors, renewable energy, and e-mobility. He specializes in thought leadership for technology applications in smart manufacturing, energy, and electrified transportation.

Crystal Ball: Quo vadis, Industry 4.0 and digital transformation?

In the latest in our Manufacturing in 2030 Crystal Ball series, we look at where Industry 4.0, transformation and digital value creation are headed

Global economic disruptions include supply chain bottlenecks, trade restrictions and rising prices for raw materials, all of which give manufacturers a big headache. Producers are also under increasing pressure to readjust their manufacturing footprint and reduce consumption to meet sustainability targets. Most manufacturers are still stuck with a geographic footprint set down in the 1980s, driven by ongoing labor arbitrage around the globe. Large factories are still predominant in low-cost regions like Asia, Eastern Europe, and South America. Accelerating trends toward automation, upskilling and high demand for customized products, combined with increasing regulatory requirements for sustainable manufacturing, are pressuring companies to rebalance this equation. To increase efficiency and respond to threats and trends, many producers have implemented Industry 4.0 technologies.

But quo vadis? Where are these trends going?

The Industry 4.0 vision – smart, networked factories, closer to customers

Industry 4.0 technologies offer no less than the ability to redesign the global manufacturing footprint, to position factories closer to markets, reduce logistical nightmares and increase the visibility of suppliers and customers.

The digital transformation offered by Industry 4.0 technology has four central goals:

1. Customization, insight-driven manufacturing and lot sizes of one

With customers increasingly demanding highly personalized products, mass customization has become a competitive playground. Western manufacturers need to differentiate their offering (via customization) from cheaper offshore competition to retain their markets. Industry 4.0 includes a wide range of technology innovations like 5G, artificial intelligence (AI), machine learning (ML), PLM and digital twins, MES, IoT platforms, and additive manufacturing (3D printing). These can support the agility, flexibility, and efficiency to offer customers such highly personalized products and services, thereby enhancing their brand experience, increasing loyalty, satisfaction, and ultimately, profitability.

Infor customers in manufacturing have switched from series production to highly customized operations in segments as diverse as the fabrication of individual sports rifles for biathlon athletes, medical science equipment, commercial laser pointing products, the fenestration industry (producers of windows and doors) and industrial cranes. Product individualization based on unique combinations of modular components and very late customer change requests have become essential ways to improve the customer experience. The vision is that consumers can switch their product configuration on the fly.

With an increasing shift of focus toward software-driven experience-based services, there will be pre-purchase changes for specific experiences. Today, some cars already come with three driving modes: sports, comfort and eco. In the future, cars may be chosen for events instead of a car’s lifetime – a camper van just for the summer holidays, an SUV for the winter holidays, a limousine for the business trip. All these will be equipped with event-based options, possibly an extra seat row for the children and special cooling options for the summer holidays, heated steering wheel and a snow-drive option for the winter holidays, and additional horsepower for a long-distance business trip.

2. Incremental innovation and transformation to product-as-a-service

Product lifecycles are becoming shorter as customer attachment to one-size-fits-all physical products decreases. Companies no longer compete exclusively on product features, instead offering value-added services, and manufacturers are adapting their operations to optimize business efficiency. In automotive, software-enabled service platforms are a new ground for differentiation, replacing hardware-related factors such as engine power and precision-engineered door handles. Success in this realm requires more knowledge about customers, software-based services and the ability to innovate and respond quickly to changing customer preferences.

3. Digital innovation reducing market distance

To reduce delays and transportation costs, leading manufacturers build smart factories closer to the customer. Redesigning the manufacturing footprint is especially imperative for the manufacturing industry, with its notoriously complex, fragile, and logistically challenging global operations and supply chain. New business models and technologies help reduce the distance to the end consumer. With digitalization, automation and robots, factories need fewer workers but more skilled ones. Thus, locations in Western countries become attractive despite higher labor costs.

With the digital revolution unfolding, there will be more ways to overcome global footprint constraints, such as these two concepts.

First, a widespread network of high-tech automated micro-factories. The micro-factory was invented in 1990 by the Mechanical Engineering Laboratory of Japan, referring to cell-based manufacturing in a multitude of small and highly automated plants, to deliver customizable designs locally. But it has not yet become widespread. Today, we observe much interest, but few operational implementations of micro-factories. Despite the appeal of quick deployment, higher flexibility, lower capital investment, and reduced environmental impact, the implementation of micro-factories is limited to start-ups and new business models. Even the discussion about micro-factories has quieted down. The assembly line still plays a major role, and the efficiency of a modern automated volume production site with just-in-sequence operations are hard to beat with a more distributed approach to production. Gartner® places Mobile Factories just before reaching the tipping point of “Peak of Inflated Expectations” on the just released Hype Cycle™ for Advanced Technologies for Manufacturers, 2023 and classifies them as: “5-10 years to mainstream adoption.”1

So, the micro-factory concept could become a strong factor to increase the value of customization and higher flexibility, fueled by zero distance and innovation in computing, robotics and AI. But it is not yet a top priority for operational executives.

Second, a relocation to high-cost countries for access to resources and customers. In contrast to the slow development of micro-factories, a counter-trend of companies setting up rather large factories in Western countries is burgeoning. First, there is a plethora of gigafactories. Introduced by Elon Musk, the term refers to giant plants to produce power units generating gigawatts of power via EV batteries. Gigafactories are set up in places like Canada, Austria, the United States, and Norway, by companies including Volkswagen, Northvolt, Miba and Frey. In addition, Infineon and Intel launched large factories in Austria and Germany to produce their core microchips, while Rheinmetall created a factory for producing electronic components for the F-35 fighter plane. This trend is driven by access to excellent logistics and highly qualified resources rather than by cheap labor.

4. Agility to deliver business and technology requirements

An effective platform enabling swift reaction to change, adjustment of the global footprint and further efficiencies via automation requires a comprehensive digital transformation. But for many organizations, challenges to connect separate technologies, true digitalization of processes and the complexity of existing systems continue to be roadblocks to executing a digital vision.

McKinsey has outlined critical success factors, including these four:

– A truly scalable operating model

– Distributed technology allowing local and independent innovation

– Access to reliable and current data when needed

– Strong adoption and change management

Cloud ERP at the core of Industry 4.0

Historically, manufacturers have architected their organizations and IT portfolios with a traditional monolithic enterprise-centric and on-premises ERP. But this inside-out model, with static, scheduled interfaces to the “outside world,” is unfit for tomorrow’s intelligent factories in response to an even more dynamic, constantly changing and truly real-time business environment. Legacy ERP systems focus on structured data from ERP transactions, not unstructured data that has become business relevant (e.g., IoT, clickstream, social media). This siloed, intra-organizational and structured-data focus does not provide the agility to adapt to and get ahead of current and anticipated business conditions.

The demands of the modern economy and the forces discussed above have led to replacement of monolithic ERP with a more modular, standardized cloud-based “hub and spoke” network approach, which can adapt and scale in line with business priorities. The capabilities to integrate, manage data, secure data and applications, and identify and provide optimal user experience have become the focus of overall enterprise strategy. The modular ERP approach is built around a core, vertical-specific ERP solution as a strategic integration platform to connect to supplemental applications, potentially from multiple vendors. This core ERP becomes the foundational platform for agility and innovation at scale. Additionally, embedded and advanced capabilities enable more intelligent automation by leveraging AI- and ML-driven insights and actions to improve the manufacturing process.

Digital cloud platform impact on time-to-value

The Infor digital ERP platform is designed to shorten time-to-value and improve customer experience to ensure success and improved business outcomes.

It is an industry-specific solution with preconfigured processes built in, and incorporates learnings from the sales process into the provisioned product. This is coupled with a heavy investment in tooling and content to shorten the initial implementation effort, cost and risk, and have the catalogue of predefined industry processes to accelerate deployment. The cloud simplifies updates and eliminates the need for major upgrades and for a large technical team to implement and maintain business applications.

It is set to become the central platform for dynamically driven innovation. Every company that joins increases the industry cloud scale in sectors such as automotive, industrial manufacturing and A&D, and accelerates the need and pace for relevant industry-specific additions. In 2030, industry communities will drive standardized cloud-based functionality based on their needs for manufacturing functionality, compliance with regulation, and process optimization through deep strategic interaction to set priorities per industry. Upgrades will be deployed immediately as standard additions with transparent and global KPIs throughout their entire manufacturing footprint. Over time, there will be a rich library of relevant tested use cases for process optimization based on AI per industry, available to all participants.

And the winner is … the smart, agile factory

Success belongs to the prepared. In today’s digitally transforming and connected discrete manufacturing industry, being prepared requires a re-evaluation of traditional business processes, technology capabilities and the main traditional asset, the global manufacturing footprint. Critical across each of these dimensions is effectively connecting systems and locations in an open and standardized structure and harnessing the power of data.

Manufacturing companies started to invest in new digital technologies such as AI to improve operational efficiency in areas such as demand forecasting, fault finding in production and warehousing. But today, most organizations struggle to roll out new technologies to the global universe. Those who will seriously invest in their digital platform to build a dynamic, intelligent and connected factory network put themselves into a favorable position to deploy consistent innovation steadily, quickly and globally. This change will not happen overnight. The move toward digital workflows and transparent open standards requires the whole organization to shift. Those who commit to that journey will be able to use the digital innovation benefits immediately to their business advantage in 2030. They will gain the ability to instantly respond to market disruptions, customer requirements and regulation, and create new products and services on the fly.

In an increasingly uncertain market environment, success will reward manufacturers that most effectively align new data management skills with modern information technology platforms to render their factories truly smart and insight driven. This includes the enablement of closeness to customers and their need for experiences rather than traditional products, decision-making adapted to swift reaction to change, and real-time, dynamic, sustainable and market-relevant manufacturing.

About the Author:

Dr. Henning Dransfeld is Director Industry & Solution Strategy at Infor. He is responsible for the development and implementation of Infor’s growth strategy in the discrete manufacturing in segments including A&D and automotive manufacturing in EMEA. Dransfeld has years of experience as an industry analyst. At Information Services Group (ISG), he was responsible for manufacturing, data analytics and IoT across Europe. He also led numerous consulting projects in these and related specialties. Prior to that, Dransfeld held positions at Ovum (now Omedia), T-Systems, Forrester and Experton.

Dr. Henning Dransfeld is Director Industry & Solution Strategy at Infor. He is responsible for the development and implementation of Infor’s growth strategy in the discrete manufacturing in segments including A&D and automotive manufacturing in EMEA. Dransfeld has years of experience as an industry analyst. At Information Services Group (ISG), he was responsible for manufacturing, data analytics and IoT across Europe. He also led numerous consulting projects in these and related specialties. Prior to that, Dransfeld held positions at Ovum (now Omedia), T-Systems, Forrester and Experton.

1Gartner Hype Cycle for Advanced Technologies for Manufacturers, 2023 Published 25 July 2023 – ID G00789107 By Marc Halpern, Sudip Pattanayak, Christian Hestermann, Alexander Hoeppe

GARTNER is a registered trademark and service mark of Gartner, Inc. and/or its affiliates in the U.S. and internationally and is used herein with permission. All rights reserved.

Extrapolating from the results of NTT DATA’s recent research report, Innovation Index: Shifting from Disruption to Growth, John Petrusick, Managing Director, Manufacturing — Data and Analytics Practice, offers insights into the future of data in the latest in MLC’s Manufacturing in 2030: Crystal Ball series.

Data-Driven Transformation and the Future of Human-Centric Innovation by 2030

By 2030, I envision a significant change where data flows freely from sources including the shop floor, enterprise resource planning systems and third-party external providers. Manufacturers will centralize, harmonize and analyze data to enable real-time action. This encompasses all actions, including automated actions, to maximize business efficiency. Doing so will impact aspects of the business ranging from daily production operations on the plant floor, to engaging customers in selling activities, to the development and testing of new products.

With respect to sales, products and services, manufacturers will create seamless customer experiences in which customers can purchase goods using their preferred interface. Infusing data into a design thinking-led approach will also improve overall experiences once the product is in use. From an operational data perspective, employees on the shop floor or within the business will see performance data in real time and act instantly.

Highly commoditized or repetitious manufacturing environments might function as a largely ‘headless’ or ‘dark’ operating environment. Such environments rely on processes that are highly routine, reproducible and repeatable. They will, therefore, be able to leverage physical robots in the ecosystem to take the place of today’s manual interventions. These environments will have a significant advantage in productivity and efficiency while improving safety. They may use technologies including robotic process automation for monitoring and control, generative AI for requests from outside observers, and physical robots to take actions when physical interventions are required. Nevertheless, I do not foresee a near-term scenario in which manufacturing is 100% automated with no human involvement. Through 2030 there will continue to be entire plants, production lines and core processes where the need for creativity will keep humans integral.

Empowering Manufacturing through Data-Driven Insights

Data’s role will evolve naturally, and part of the role will entail solving problems. But the primary function data will serve is to enable insights that guide the actions of individuals, software or machinery so that they deliver increasing business value.

Currently, the data sphere focuses on providing high-quality, reliable data to manufacturing business actors — humans, software, physical robots and so on. These actors need specific analytics or insights in forms such as real-time or near-real-time Key Performance Indicators from a production line on quality to make value-adding decisions. When such data indicates deteriorating quality, we may need to halt the line and perform a root cause analysis to remediate the issue to re-gain performance with thresholds.

In a preventive maintenance scenario, telemetry data from machinery might show that a machine will fail within two hours. A worker would then receive an alert prompting them to reallocate capacity from that line to others, if possible, to allow for necessary maintenance. Alternatively, in a product development scenario, we might be able to design and test a product virtually. This will help manufacturers create the right product to the correct specifications the first time around, thereby reducing time to market.

As the right analytics become available in 2030 and beyond, manufacturers will gain the real-time insights to deploy end-to-end automation using autonomous tooling. Automation may extend even to the point of delivery, potentially with no human intervention. This data-driven automation will create additional value through improved efficiency and shorter time to revenue generation.

Unlocking Future Manufacturing Success for Enhanced Plant Operations

Currently, we are observing advantages in various aspects of plant operations such as preventive maintenance and quality improvement. For example, vision robotics is already providing assessment data at all stages of manufacturing, from raw materials to finished products. Moving toward 2030, we see manufacturers that start or continue to follow data and analytics best practices gaining significant benefits. These benefits will be in part due to the advantages of an expanded role for AI and the benefits it can provide, enabled by continuously improving data quality. In combination with the Internet of Things (IoT), AI will have the potential to help manufacturers build factories that are more agile, transform their workforce, make significant progress against sustainability objectives, improve security and compliance, and more. Again, this is contingent on establishing the right data standards and practices.

Building Technology Ecosystems that Unleash Data’s Power

Realizing the potential of data as we are discussing it here will not require any singular technology, but rather an ecosystem of solutions working in concert.

Even today, when we consider the data stack, we emphasize cloud-native data solutions that shift away from monolithic platforms towards an ecosystem of best-in-breed, loosely coupled and high-use technologies and tools.

Data in 2030 will similarly require an array of elements. These range from IoT sensors on machines — many of our clients already have such systems in place or are testing them — to the ability to centralize this data and provide global visibility to it. To cite just one example, manufacturers will increasingly implement machine vision, which involves converting video into data for analysis across a wide variety of use cases from quality inspection to safety compliance.

Finding Future Success by Navigating Data’s Complexities to Overcoming Storage, Reliability, and Analytics Challenges

Data storage and reliability challenges I alluded earlier to the need for data centralization. Many of our clients have already conducted pilot projects or have implemented some of the technologies previously discussed in various plants. But most have yet to successfully centralize their data for global visibility. At the heart of this issue will be the need for investment as, historically speaking, manufacturers have not made the significant investments in their data ecosystem needed to resolve this key dependency.

On the flip side, despite the importance of data centralization, there are cases where manufacturers will need to balance their need for centralization versus a need for rapid analysis and action. In such cases, the challenge will be how to embed intelligence into a local system and thereby enable machine-learning-based decision-making at the edge.

Both challenges will be pervasive. Consider a global manufacturer or a multi-site operator aiming to achieve visibility across all their operations. They may have plants that are almost entirely automated with minimal human intervention and others that have a larger human presence. Both environments present the need for clear visibility into each plant’s operations via data, so the different plants might all require a sort of “control room” view. The first step to enabling that view is to store the data on which to base the view. The data may reside in a centralized location or at defined edge locations.

The next step is to ensure the data’s reliability, whether the data is in storage or in transit. This phase involves a data management component that underpins everything before proceeding to the analytical stage.

Data analytics challenges

After overcoming data storage and reliability challenges, manufacturers can shift to the challenge of data analytics. For most manufacturers, the data management in place today is not at a level where they can trust the data without question.

At the same time, there are potential solutions to these challenges from which two separate elements come to mind. First, from a data management perspective, manufacturers could use machine learning algorithms to conduct quality checks and make recommendations on how to master the data. This process is crucial to effective analytics.

The second element pertains to both the techniques of analysis and the human factor involved. Often, achieving success with analytics depends on clearly defining the question we are trying to answer and the action we aim to take. When discussing data and analytics, our shop floor personnel may say they lack the needed technical knowledge. But the reality is, they do not need to understand all the complexities of data. Instead, as data professionals or leaders, we should focus on the actions they take and the decisions they must make in their roles, and develop analytics capabilities accordingly.

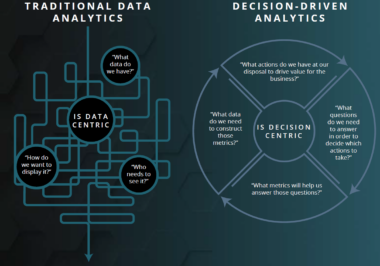

Traditional data analytics versus decision-based analytics

Anticipating the evolved and central role the workforce will play in manufacturing in 2030, decision-driven analytics is about determining the necessary actions the workforce must take to create value in a business. First, we need to ask the right questions to guide these actions. We then identify metrics or measures to establish decision points and gauge results. Lastly, we must determine the type of data needed to create those metrics and measures.

The decision-driven approach to analytics can be simplified to four elements: actions, questions, metrics and data. The goal is to understand the actions that create value in a business, then enable these with data strategies and analytics that also yield value.

Fostering Data Literacy and Collaboration to Bridge the Gap Between IT and Business for Action-Oriented Analytics

From a technologist’s perspective, it is essential to understand what is happening in the business and what actions or decisions we are informing or enabling with the technologies we are deploying. As such, IT organizations must enhance their engagement with the business. Simultaneously, business actors might need to upskill their data comprehension.

This does not mean that all business actors must learn to write SQL queries and Python scripts or be up to speed on the latest data science modeling techniques. Rather, it means they must have the requisite level of data literacy to understand the actions they take in their business and how data could help them make better decisions. Approaching it from this angle will help manufacturers find success, in part because business teams and IT organizations are thinking similarly and working towards achieving specific business outcomes.

Infographic. Aspirent, an NTT DATA Company.

To bridge the gap between IT and business teams, we have found success using a structured Decision Architecture framework focused on the following critical topics:

- What actions do we have at our disposal to drive value for the business?

- What questions do we need to answer in order to decide which actions to take?

- What metrics will help us answer those questions?

- What data do we need to construct those metrics?

This decision-driven framework offers manufacturers a more targeted, action-oriented approach to data and analytics that enables the creation of specific business cases and a clear path to unlocking their data’s potential.

Empowering Manufacturing Excellence by Navigating Data-Driven Insights for Collaborative Success and Outcomes

Ultimately, data analysis and subsequent actions depend on the workforce. It is essential to ensure that we provide data in a format that the workforce can use effectively. Similarly, the speed and effectiveness with which currently top-of-mind technologies can grow is constrained by the need for data that is accurate, complete, reliable, relevant and timely. Data and analytics reside at the core of high-value business outcomes — whether driven by the workforce, AI or combinations thereof. Potential outcomes range from creating more resilient supply chains to accelerating innovation and delivering new services to engaging customers in new ways.

In short, although we have covered a lot of ground here, my single most important piece of advice is to create and maintain a focus on driving collaboration at the intersection of IT and business teams with a focus on the business context and outcomes of data usage. By doing so, manufacturers will be able to increase the business value that data solutions create and avoid complications preventing the realization of that value.

If this data discussion has sparked your interest, we invite you to check out our infographic “Innovate Confidently with Data-Driven Decisions.” It features relevant data from the 2023 NTT DATA Innovation Index.

About the Author

About the Author

John Petrusick is a Data and Analytics Managing Director at NTT DATA, serving as the Manufacturing Industry Lead. In his role he advises manufacturers on how best to leverage their data to create business value-driven, actionable, and analytic insights to increase efficiency, sustainability, and competitiveness. He is passionate about helping clients solve their data challenges, specifically in data governance, architecture, engineering and integration, advanced analytics and business intelligence, and intelligent automation, as well as helping them implement strategies to drive digital transformation.

Six Key Takeaways: Be ‘Predictive’ to Be ‘Preventive’

A recent MLC Master Class focused on how manufacturers are using condition monitoring and predictive maintenance to avoid downtime, maximize productivity, and enhance operational efficiency. Micah Statler, Director of Industrial Technologies at Advanced Technology Services (ATS) shared his experiences and expertise in an engaging conversation with MLC’s Senior Content Director, Penelope Brown.

Here are six key takeaways from their discussion:

1. Transforming data charts into prescriptive actions

According to Statler, no matter how mature a maintenance organization is, any change is difficult and change management techniques are important because there are outside influences and new tools involved. But transforming data from a squiggly line on a chart into action is paramount.

“The biggest challenge facing any manufacturers out there today is not necessarily the collection of data, but the interpretation of that data to gain a level of insight that allows them to be successful in taking action and recognizing a return,” Statler said.

Figure 1 – maintenance maturity levels

He identified four maturity levels for overall equipment effectiveness (OEE) and uptime reliability: reactive, preventative, predictive, and precision. To find where an organization falls on this maintenance maturity scale, Statler provided a few assessment questions:

- Are you planning your work?

- Are you able to put a plan forward and able to execute that without a lot of schedule breakers?

- Are you able hit your production targets?

2. Eating the condition monitoring elephant one bite at a time

For companies looking to implement best practices for condition monitoring, don’t try to boil the ocean. Instead look to where you’re seeing the most impactful downtime and eat the elephant one bite at a time. Some areas to look at first include where you are spending the most on MRO parts and repairs, what problems cause your most expensive maintenance labor, and what assets experience issues regularly.

Statler also recommended avoiding a single firefighter to look at these issues.

“We have an opportunity to do it in a much more efficient way, and also in a way that doesn’t mean it is an individual contributor, and therefore your progress – if you’re not dependent on an individual – can’t backslide from it. It’s more ingrained in your culture and it just becomes how you do business,” he said.

3. Combatting alert fatigue with collaboration

“Cross-functional teams are critical. It’s not just about the data collection,” Statler said. “We have to do something with that data, and we have to really align on what the ultimate outcome is.”

Further, to avoid what Statler called “alert fatigue,” there must be trust and the right level of communication between the factory floor and those asking them to take an action from the data. Change management comes into play here, and the collaborative team – including data scientists, developers, technology departments and the maintenance team – needs to be realistic about how mature a company’s maintenance program is.

4. The beautiful circle: AI and data analytics

Analytics and statistical process control has been around for a long time, but newer technologies like artificial intelligence (AI) help manufacturers see broader trends and take findings from one measure to another.

To illustrate this, Statler mentioned the core four traditional predictive maintenance analysis: oil, vibration, ultrasonic, and thermographic.

“What we’re able to do with the tools that we have today is, say there’s something else that I want to measure, we can apply a lot of the same models to that,” he said. “We’re getting a lot better at being able to not only say there’s a problem, there’s a change in that trend, but being able to predict what is the remaining useful life of that component that’s being monitored.”

“Ultimately,” he said, “we don’t want to get to a position where, when we notice a change in trend, we make a component change. We want to be at a point where we’re able to make minor but precision adjustments to anything that’s being measured.”

This is where AI and advanced analytics come into play.

“The better we can deliver the service, the better we can train the model, the better we can deliver the service. It’s a beautiful circle,” Statler concluded.

5. Avoiding “service on a stick” partners

For those looking to partner with a technology provider to achieve better predictive maintenance, it’s as important to look at what a company does now as it is to look at the company’s vision for the future.

“You want to pick a partner that is going to grow long-term with you and be able to work within the platforms and the tools and the data sets that you have today and in the future,” said Statler.

He also recommended looking at the service offering, itself: is it an end-to-end solution that not only collects the data and monitors the equipment but also helps you interpret the data in real time?

Statler cautioned against providers who offer one-size-fits-all solutions, and likened them to getting a plain corn dog at the fair.

“There are an infinite number of options out there for you to buy hardware, tons of platforms available, and a lot of them have coupled those together,” he said. “Internally, we call that ‘service on a stick.’”

6. A fully digital future for condition monitoring and predictive maintenance

Condition monitoring and predictive maintenance are primed for a future full of innovation.

“The technology will be accelerating so quickly and be so ingrained that we’re not even going to notice that the industry has transformed. It will be fully digital,” he said.

In fact, he pointed to technologies that we’re already seeing today. In particular, smart hands or augmented reality tools will transform the business, and people will view dashboards through heads-up displays in proximity of specific assets.

Beyond the technology itself, Statler expects to see a shift in the technical capabilities of on-site staff as well.

“There’s going to be a real integration of vendors with technology vendors and equipment vendors being able to, real-time, see what maintenance technicians see – and that’s where the smart hands come into play,” Statler said.

MLC members may access the full recording under Master Class in the Resource Center of the Member Dashboard.

More information about the Master Class Series is available online.

Crystal Ball: A Futuristic Workforce Odyssey

For humans and machines to work together by 2030, the workforce evolution must start now

Extrapolating from the results of NTT DATA’s recent research report, Innovation Index: Shifting from Disruption to Growth, Kim Curley, NTT DATA’s Digital Evolution Leader and Vice President of People & Organization, shares her insights about the future of the manufacturing workforce in the first of our Manufacturing in 2030: Crystal Ball series.

Picture this: the year is 2030. Across the U.S., the manufacturing workforce has evolved into a symphony of humans and machines working in harmony. This dramatic transformation has made the workforce a technology-enabled powerhouse. Artificial intelligence, robotics, and virtual reality lead the charge, transforming the factory floor into a buzzing and orchestrated hub of activity.

Workers use advanced technologies to perform their tasks more efficiently and safely, collaborating seamlessly with their robotic counterparts. The shop floor thrums with the smooth whirr of precise machinery and the hum of advanced systems. Augmented reality displays guide workers through complex tasks. And to make this possible, the workforce has become a melting pot of diverse talents and skills that is continuously learning and developing

It is a rosy view of the future, but realistic based on current data and trends that illuminate a path to this future state.

Changing Skillsets for 2030