How Best Practices in Data Analytics Drive Maintenance Maturity

Insights that convert into actions can improve equipment reliability, span the enterprise, and boost the bottom line.

TAKE AWAYS:

● Using data and analytics for condition monitoring can eliminate unplanned downtime and allow for improved equipment reliability.

● Centralizing maintenance roles and utilizing remote support can help manufacturers alleviate labor scarcity and maximize their technical teams.

● Machine health monitoring can trigger corrective actions to be scaled across multiple production lines or multiple sites.

Manufacturers are acutely aware of how machine health affects production throughput, particularly plants operating in a throughput-constrained mode. Without sustainable equipment uptime, schedules are missed, orders go unfulfilled, revenue is lost, and unplanned labor and repair costs are incurred.

A significant factor impeding the achievement of operational goals is the widespread, protracted shortage of asset reliability and maintenance talent. Fortunately, technology can alleviate this challenge.

The burgeoning depth and breadth of condition monitoring analytics technologies offered by countless solution providers aims to eliminate unplanned downtime. The core value of machine condition monitoring is twofold: (1) drive best practices in reliability and maintenance; and (2) mitigate the skills gap now and into the future. Its primary goal is harvesting analytical insights directly from machines to identify the opportune time to service degrading critical equipment and components — not too early, nor too late.

“Gaining maximum value requires putting the data and analytics to good use.”

Mastering how the condition data is harnessed, analyzed, and operationalized is key. With digitalization boosted by the industrial IoT, such as wireless condition monitoring sensors, plants can collect and centralize for analysis unprecedented quantities of real-time, streaming asset condition and performance data, along with batches of intermittently connected or locally captured data. Gaining maximum value from this approach requires putting the data and analytics to good use.

Operationalizing Data Analytics

Many plants lack the internal resources to leverage machine condition monitoring for troubleshooting and repairs, let alone navigate the complexities of developing scalable analytics solutions. The prior model of staffing qualified, dedicated at every manufacturing facility is no longer sustainable.

Industrial service providers are responding to this reality by adapting and optimizing their own technology and methods, while developing new ways to provide actionable remote support to the factory floor. Over the past 12-15 years, the aging manufacturing talent pool and increasing demand for domestic manufacturing compelled leading service companies to refocus on centralizing core roles, such as predictive maintenance specialists, reliability engineers, and high-level positions.

This development is driving a cultural shift in manufacturing. Internal plant maintenance teams are not inherently inclined to ask for help, but once they begin accepting virtual support, they can transition from their singular plant focus and leverage their skills out to other locations.

Machine health monitoring is also a paradigm shift for the remote support providers, who now actively pull condition data for analytical insights and translate it into action on the factory floor. For instance, when an alert is received at a centralized technology center that an asset condition threshold has been breached at a certain plant, an expert can reach out to the appropriate individual on the factory floor to provide crucial guidance remotely, in layman’s terms.

“The core value of machine condition monitoring is twofold: (1) drive best practices in reliability and maintenance; and (2) mitigate the skills gap now and into the future.”

Rather than details such as the frequency, hertz, and amplitudes of the waveform, what a technician really needs to understand is, for example, that it looks like a specific coupling is coming loose. In this example, that would mean they need to take that machine out of service, validate that the motor is meeting its alignment specifications and everything is in safe working order, and then torque the coupling to its proper specification. Additional details or step-by-step instructions can be provided by the remote service expert to the asset-facing technician via a mobile device.

Moreover, this new approach to monitoring and analytics is driving significant innovation in maintenance automation processes. A simple example is instead of regularly pumping grease into an asset, data analytics from that piece of equipment can trigger a command to an auto-lubricating device bolted onto the machine to automatically inject the correct amount and type of grease into the equipment. This optimizes the process while also eliminating the need to involve a maintenance technician.

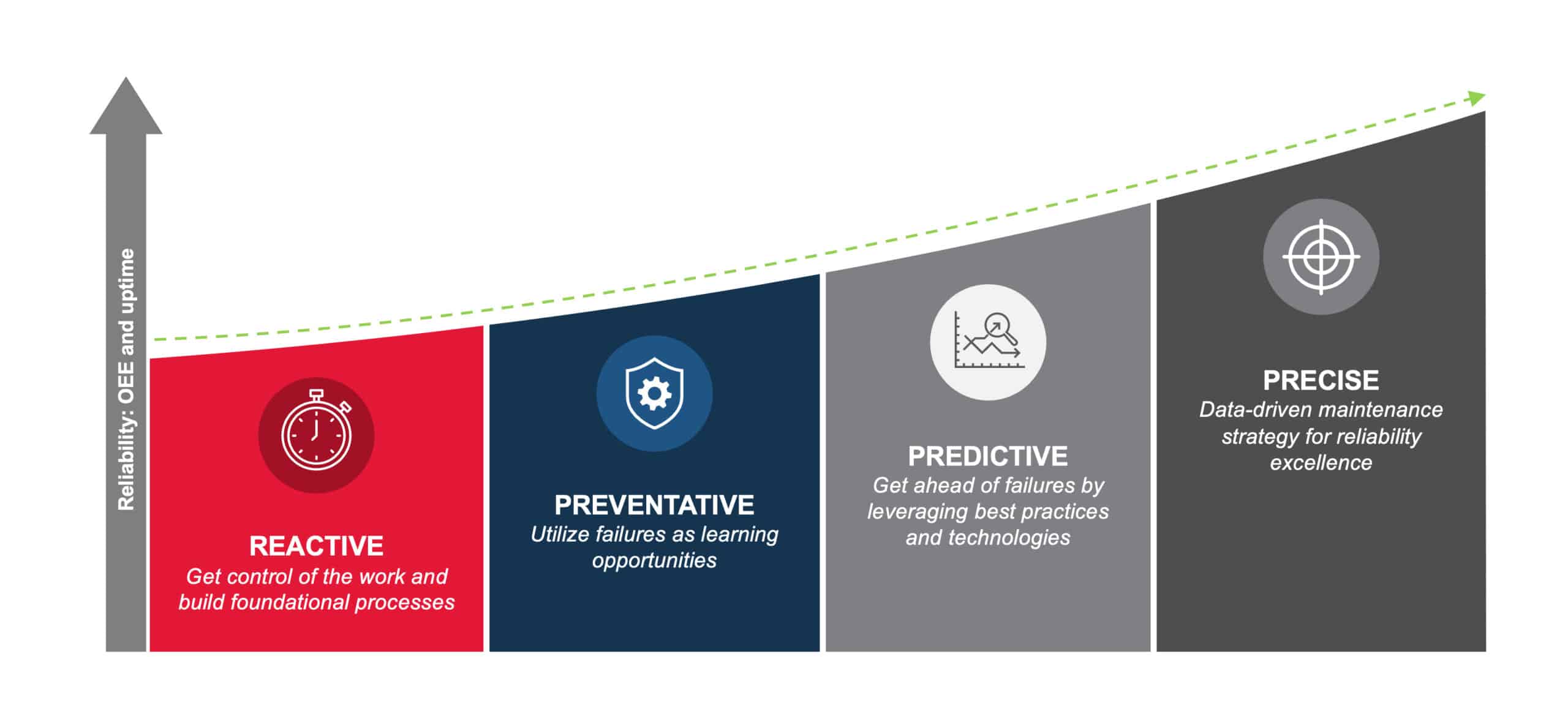

Figure 1 – Accelerating Maintenance Maturity

The Evolution of Maintenance Philosophies

Maintenance philosophies have changed markedly over the years (Figure 1). For a long time, maintenance meant running equipment until it breaks, and then fixing it, though this caused excessive unplanned downtime. When preventive maintenance practices emerged, time- and usage-based plans and routes were developed to keep the equipment in better condition, though the risk of downtime from over- or under-maintenance was still a concern.

Condition-based maintenance practices flourished when skills gaps intensified the need for labor efficiency. Having sensors continuously monitor and measure machine condition parameters and trigger alerts when a given threshold is met allows scarce labor to be applied to situations that actually need attention.

“Internal plant maintenance teams can utilize virtual support to transition from a singular plant focus and leverage their skills out to other locations.”

The latest realm of maintenance maturity is predictive maintenance — applying condition analytics and prognostics to predict when an asset is likely to fail, forecast the asset’s remaining useful life, and plan maintenance processes, people, and parts with precision to get the maximum life out of the equipment and components. Ideally, this approach leverages not only real-time condition monitoring data, but also historical trends and contextual information such as environmental conditions, process output, and maintenance histories.

Continuous condition monitoring analytics are central to the highest level of maintenance maturity, known as precision maintenance. It allows the work to be predicted and stretched out for as long as possible, maximizing the utilization of time and labor while maintaining the highest asset availability and throughput opportunity.

Extending Maintenance Optimization

Condition monitoring analytics enable plants to optimize their asset maintenance practices and migrate to an enterprise-wide predictive maintenance philosophy. Even non-critical assets that remain on route-based preventive maintenance schedules can benefit from predictive analytics. This is because manufacturing facilities frequently operate identical or similar types of equipment across multiple lines within a plant, and across any number of sister plant locations.

Specifically, any machine health finding that triggers a corrective action can be leveraged across other assets that have, or are developing, a comparable condition. Additionally, the knowledge gained from condition analytics and root cause identification can help to refine maintenance plans and intervals for all equivalent equipment. Extrapolating the findings to additional equipment in this manner optimizes both preventive maintenance schedules and predictive maintenance activity, further reducing unplanned downtime and extending the mean time between failures.

“The knowledge gained from condition analytics and root cause identification can help to refine maintenance plans and intervals for all equivalent equipment.”

A good case in point is when a specific lubrication issue at a plant was identified as the root cause of unplanned downtime. A little digging into their maintenance processes revealed that the preventive maintenance plans did not include the appropriate tasks to prevent the lubrication condition. That deficiency affected not just that single piece of equipment, but all equipment of that type, across all facilities. The results of that initial finding led to adjusting all the maintenance plans for 26 pieces of equipment across 12 facilities, increasing efficiency and preventing similar failures.

Reaping Strategic Benefits

The advantages of mastering this strategy are manifold. Consider a plant that purposely overheats aggregate to make sure it is completely dry. It may consume twice as much natural gas than is really needed to properly manufacture the product. From a financial perspective, passing that extra cost onto the consumer creates some competitive challenges for the manufacturer. From a sustainability perspective, excess emissions and gas transport requirements create a larger carbon footprint. With proper temperature monitoring, such challenges can be avoided.

Here are three of the primary benefits of operationalizing condition monitoring analytics:

- Planning and scheduling: Having access to machine health data analytics enables data-driven prioritization of work planning and scheduling for consequential labor and cost efficiencies. Online condition monitoring allows issues to be addressed as they arise, based on detectable early warning signs, with well-planned and strategically timely corrective actions. Since time- and cycle-based maintenance plans are conducted regardless of an asset’s actual condition, changes go undetected between routes, and random failures are routinely missed.

- Equipment reliability: Continuous machine health monitoring allows plants to move quickly on resolving predicted failures, maximizing uptime rather than reactively repairing failed equipment or components. Monitoring can reveal sudden large changes such as those attributed to a process change or machine crash, or gradual changes over time, including micro trends. By implementing AI and machine learning algorithms based in statistical process control, the degree of change can be tracked on an ongoing basis, and insights can be gleaned to determine reliability engineering needs and root causes.

- ESG and sustainability: Actively monitored and well-maintained equipment tends to operate in a highly efficient and effective manner. Likewise, when environmental conditions such as humidity, temperature, and cleanliness of the air are continuously monitored and proactively maintained, the benefits to human and machine health are great. Conversely, improperly maintained equipment running under production load is more prone to energy waste, raw material waste, scrap, quality defects, minor stops, equipment outages, or catastrophic failure.

Consider Monitoring as a Service

Many plants want to move to a condition-based mindset but lack the engineering and development capabilities in maintenance and IT to pull together a robust package on their own. Choosing remote condition monitoring as a service may be the answer for plants that are short on time and internal technical talent.

Industrial service providers with extensive experience in predictive technologies are adept at designing, implementing, and managing fully integrated condition monitoring analytics solutions. Those with the added capability of providing centralized, remote support for hundreds of manufacturers in multiple industries are uniquely well versed in operationalizing analytics in plants and across plant sites. M

About the author:

Micah Statler is the Director of Operations at Advanced Technology Services