The manufacturing industry has spent a lot of time, effort and money on making its processes more efficient over time. And now the industry is investing in the Industry 4.0 philosophy to minimize wastage and downtime, leveraging technologies including 3D printing, digital twins, and predictive maintenance. Powering all of these investments is data.

Late last year I had a number of conversations with manufacturing professionals who manage products throughout their lifecycles – from the 3D CAD design phase, through review, fabrication, sales and marketing, and even further into customer usage and after-sales. They each told similar stories of breakdowns in the processes for creating, distributing, and consuming content that transfers vital knowledge about their products. In addition, they all identified significant negative impacts stemming from these problems. Errors, delays, and missed sales opportunities were frequent complaints.

I came away wanting to know more about these problems, their outcomes, and the underlying causes. What is driving ineffective product documentation workflows and processes at organizations that otherwise appear to be investing heavily in efficiency-based initiatives and cutting-edge tech?

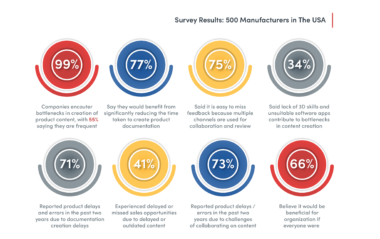

In a bid to find out, my company, Canvas GFX, surveyed over 500 manufacturing professionals across a broad range of verticals, including automotive and electric vehicles, aerospace and defense, new space tech, industrial machinery, and more. The results showed these challenges exist widely across the manufacturing sector, suggesting an endemic and interconnected problem.

We’ve dubbed this problem Product Communication Disorder. For many companies, Product Communication Disorder is perceived, managed – and often tolerated – as a series of departmental workflow challenges. The data suggests the problem cannot be solved unless assessed and addressed with a company-wide perspective.

Where have manufacturers gone wrong?

There are three distinct stages within documentation and knowledge transfer where problems arise, the first being the creation of product content.

As it stands, creating product communication content is time-consuming and complicated, requiring input from multiple team members across an organization. Our research highlighted how critically deficient current workflows are, with clear room for improvement. The stats lay the issue bare, with over 95% of manufacturing industry professionals reporting that projects or products at their company had suffered errors or delays as a result of inefficient workflows for the creation of product communication.

But the problem runs deeper than content simply being late or too time-consuming to create. While the data says these are both true, our survey also suggested that the processes underpinning the creation of content are themselves flawed. For more than one in three respondents (36%) workflow bottlenecks stemmed from too many people being involved in content creation. Meanwhile, the lack of skills or software needed to be able to properly visualize 3D models, the basis for many documentation illustrations, was cited by one third of respondents.

Collaboration is another area fraught with challenges. In fact, 73% of respondents in our survey said they had experienced product or project errors or delays in the past two years as a result of difficulty collaborating on content.

Just as content creation at manufacturing companies is fragmented in terms of departments, skills and software, the collaborative process also appears to want for some kind of central management. According to almost three quarters of survey respondents, a primary problem appears to be too many channels (including email, Microsoft Teams, Slack, and other voice and video calling solutions) being used to manage collaboration, review and feedback on product content. The result of this vital communication happening across a range of channels according to 3 in 4 respondents is that it is easy to miss feedback on important documentation and content.

Lastly, the survey revealed serious concerns around the ability of workers to access the most up-to-date documentation materials. For many organizations this appears to be a struggle, while the problem is aggravated by managing a range of different content formats. It’s vital to remember that consuming content is what this entire process is about.

Worryingly, 85% of respondents said that outdated documentation in circulation had resulted in errors and delays over the last four years, and over a third (36%) said their company struggled to manage the rate at which content becomes outdated. More alarming still is the large proportion of respondents who conceded that their company has difficulty ensuring everyone who needs access to content is able to access the most up-to-date version of each document (54%).

Solidifying Industry 4.0 gains

The overarching issue is that manufacturers spend heavily to update their processes to reduce defects and ensure products make it to market on time, documentation issues are continually undercutting those investments.

Perhaps the starkest illustration of the problem lies in the fact that 73% of respondents felt that inefficiencies in their product communication processes were undermining gains made through other technology initiatives.

But it’s not all doom and gloom, and there is a silver lining here. The findings pointed to evidence that manufacturing companies are looking to cure the problem, rather than simply manage the pain. While the data is clear, so are the actions companies can take.

By addressing their problems in product documentation, companies can take a huge leap in realizing the full potential that Industry 4.0 offers and maximize their investments in it.

About the author:

About the author:

Patricia Hume is Chief Executive Officer of Canvas GFX.